6 Ways Flooring Can Improve Safety in the Meat Processing Industry

In the fast-paced and demanding world of meat processing, safety is paramount. The meat processing industry faces unique challenges due to the nature of its operations, including the handling of slippery, wet, and often acidic substances. One key element that can significantly enhance safety in this industry is the choice of flooring.

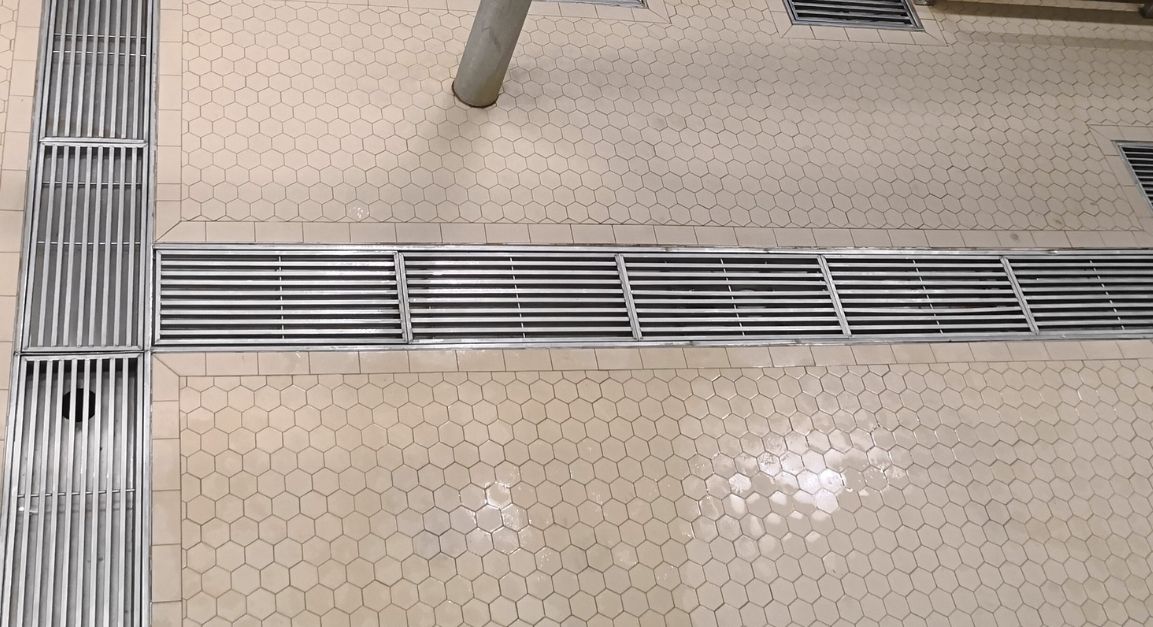

Slip-Resistance

Slip and fall accidents are a common hazard in meat processing facilities, where floors are often wet and greasy. Choosing flooring with excellent slip resistance, such as Vibroser’s Acid-Proof Tiles, can dramatically reduce the risk of accidents. These tiles are specially designed to provide exceptional traction, even in the presence of liquids, ensuring that workers can move safely and confidently.

Chemical Resistance

Acids and chemicals are frequently used in meat processing for various purposes, including cleaning and disinfection. Vibroser’s Acid-Proof Tiles are specifically engineered to withstand exposure to acidic substances, ensuring that the flooring remains intact and safe. This resistance prevents floor deterioration and minimizes the risk of accidents caused by damaged flooring.

Hygienic Properties

Maintaining a hygienic environment is crucial in the meat processing industry to prevent contamination and ensure product safety. Vibroser’s Acid-Proof Tiles are not only resistant to chemicals but also easy to clean and sanitize. Their smooth, non-porous surface prevents the accumulation of bacteria and pathogens, promoting a safer and more sanitary workspace.

Durability

Meat processing facilities operate around the clock and endure heavy traffic, including the movement of equipment and the processing of meat products. Vibroser’s Acid-Proof Tiles are renowned for their durability and long lifespan, making them a cost-effective choice for the industry. Their robust construction ensures that the flooring remains safe and intact even under challenging conditions.

Temperature Resistance

Meat processing often involves extreme temperature fluctuations, from hot cooking areas to refrigerated storage spaces. Vibroser’s Acid-Proof Tiles are designed to withstand these temperature variations without cracking or deteriorating, ensuring that the flooring maintains its safety properties even in demanding thermal environments.

Customization Options

Every meat processing facility has unique requirements and layouts. Vibroser offers customization options for its Acid-Proof Tiles, allowing them to be tailored to the specific needs of your facility. Whether you need specific colors for designated areas or custom sizing, Vibroser can provide flooring solutions that enhance safety while meeting your operational needs.

FAQs

Q: How do you think the use of Vibroser’s Acid-Proof Tiles in meat processing compares to conventional flooring options in terms of safety and hygiene?

A: Vibroser’s Acid-Proof Tiles excel in safety and hygiene compared to conventional options. Their slip-resistance and chemical resistance make them superior for maintaining a safe and hygienic environment in meat processing facilities.

Q: Considering the various challenges faced by meat processing facilities, which industries or sectors do you think could also benefit from using acid-proof and slip-resistant flooring like Vibroser’s tiles?

A: Besides meat processing, industries like dairy processing, beverage manufacturing, chemical processing, and pharmaceuticals could significantly benefit from acid-proof and slip-resistant flooring due to similar safety and hygiene challenges.

Q: If you have experience with flooring solutions in industrial settings, what advice or insights can you share about selecting the right flooring for specific operational needs?

A: Understanding the specific operational demands, such as exposure to chemicals, moisture levels, and traffic patterns, is crucial. Opt for flooring that aligns with these needs, prioritizing factors like durability, slip resistance, ease of maintenance, and compliance with industry regulations for optimal safety and performance.