Chemical Resistant Tiles | Acid Proof Tiles

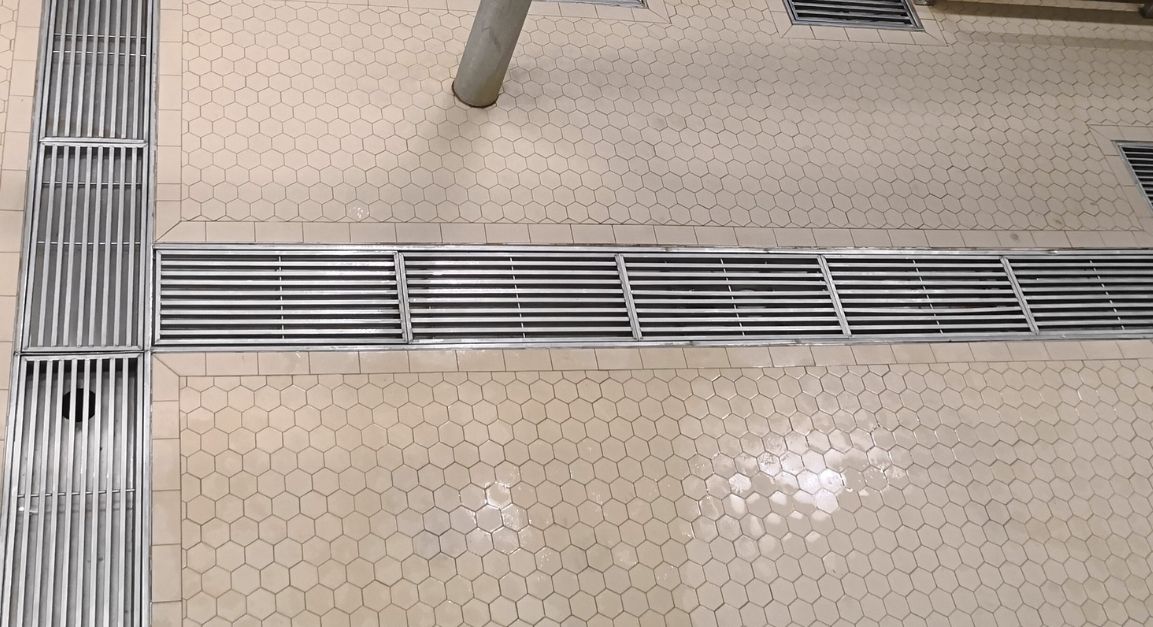

Industrial facilities use chemical resistant tiles to obtain a longer-lasting floor compared to similar floor coverings. Industrial areas prefer chemical resistant tile flooring, also known as acid proof tiles, as floor covering because it offers hygienic and long-lasting use. It is suitable for use in all areas where hygiene is at the forefront, especially in the food sector. These tile types, which offer healthy protection for floors exposed to chemicals, also create an easy and special usage opportunity in terms of cleaning.

Key Features of Chemical Resistant Tiles

- High Resistance to Chemicals: Designed to withstand acids, alkalis, and other corrosive substances.

- Non-Porous Surface: Prevents absorption of liquids, reducing the risk of stains and bacterial growth.

- High Durability: Can endure heavy mechanical loads and abrasive conditions.

- Slip Resistance: Provides a safe working environment by reducing the risk of slips and falls.

What are Acid Resistant Tiles?

Facilities use acid-resistant tiles as hygienic floor coverings. Thanks to their durable structures, acids, and chemicals do not affect tiles and offer long-lasting use. It is one of the strongest and most durable materials in its field. These tiles, which manufacturers use in areas where facilities require high hygiene standards, have various features;

- Matte structure and thus does not slip or wear.

- Substances such as acid and oil do not affect it, especially chemical substances, and maintains its robustness.

- It is resistant to high temperatures and does not show any deformation.

- Also, it is resistant to heavy materials, does not cause any cracking or deterioration. In this respect, it has higher durability than concrete.

- In addition to its easy-to-clean structure, it does not spontaneously produce bacteria on the surface and offers hygienic use.

- Thanks to its natural material, it does not change color depending on time and use. It has environmentally-friendly features.

In this respect, chemical-resistant tiles are suitable for all areas, especially in food production facilities. Moreover, thanks to its long life, it creates an economical choice.

How Do You Fix Chemical Resistant Tiles?

Chemical resistant tile laying is done very easily. Compared to similar materials, it does not require pollution or intense efforts during application to the floor. The adept must first clean of dirt existing concrete floor and then pour the mortar into fixing the chemical resistant tiles on the floor. After pouring the mortar, the applier makes improvements on the ground to create a smooth surface.

In this way, the floor, which has a flat and clean structure, becomes suitable for the placement of tiles. Next, adept place tiles carefully on fresh mortar. In the meantime, we use bonding materials with high holding properties and are suitable for tiles. After the stage, the master should do pre-compacting and not leave any gaps between the floor and the tiles. Compression is an essential detail for the placement of tiles resistant to chemicals, and the master should treat with care not to impair both appearance and usage. At the last stage, the master completes the process by applying the vacuum process.

These tiles, which are easily fixed compared to similar coatings, do not require detailed maintenance and provide significant advantages to their used areas.

Applications of Chemical Resistant Tiles

- Food Processing Plants: Ensuring hygienic and safe working conditions.

- Pharmaceutical Facilities: Maintaining clean and contamination-free environments.

- Chemical Laboratories: Withstanding exposure to a variety of chemicals without damage.

- Manufacturing Plants: Providing a durable and low-maintenance flooring solution.

Investing in chemical resistant tile flooring is a strategic decision for any industrial facility aiming to enhance its operational efficiency, safety, and hygiene standards. By choosing acid proof tiles, businesses can ensure a durable, easy-to-maintain, and hygienic flooring solution that stands the test of time.

Are Porcelain Tiles Acid Resistant?

Porcelain tiles are produced as acid-resistant. In this way, it makes a much safer and healthier floor possible during use in industrial areas. Since the floor is important for both the employees and the customers for the facilities and businesses, the floor must meet the necessary production conditions. Thanks to tiles resistant to chemicals, an effective solution is provided against the problems that may occur on the floor. These tiles, which also have antibacterial properties, prevent the formation of bacteria on the floor for environments where hygiene is important. Porcelain tiles stand out as the best flooring solution preferred by businesses and large facilities, as they are resistant to acids and oils, especially chemicals.

What is Acid Tile?

By definition, Acidproof tile is a floor covering that has low water absorption value, is easy to clean, is resistant to acid, oil, and similar chemicals, and does not produce bacteria. From businesses to large facilities, the use of acid tiles has great advantages. Thanks to these chemical-resistant tiles, the floor is made hygienic and durable. Tiles, which are resistant to impacts and pressures, and chemicals, provide an important opportunity; as a comprehensive and integrated floor application solution with all these features.