Dairy Plant Flooring Contractors

In the dairy industry, the quality of your facility’s flooring plays a crucial role in maintaining hygiene standards, ensuring safety, and optimizing productivity. When it comes to dairy plant flooring, it’s imperative to work with experienced contractors who understand the unique requirements of the dairy processing environment. In this blog post, we will delve into the essential considerations for selecting the right dairy plant flooring contractors to ensure the smooth operation of your dairy facility.

Expertise in Dairy Plant Flooring

One of the most critical factors to consider when choosing a contractor for your dairy plant flooring is their expertise in the field. Dairy plant flooring is not the same as standard industrial flooring; it demands specialized knowledge of the dairy industry’s specific needs.

Look for contractors who have a proven track record of working with dairy plants. They should be well-versed in the materials, coatings, and installation techniques that are best suited for dairy processing environments. An experienced contractor can recommend flooring solutions that are resistant to chemicals, easy to clean, and capable of withstanding heavy equipment and foot traffic.

Compliance with Hygiene Standards

Dairy processing facilities are subject to strict hygiene standards to ensure the safety and quality of dairy products. When hiring flooring contractors, ensure they are well-informed about these regulations and can guarantee compliance.

Experienced dairy plant flooring contractors will be knowledgeable about local and international standards relevant to dairy processing. Compliance with these standards not only ensures product safety but also helps avoid costly penalties and shutdowns.

Customized Flooring Solutions

Every dairy plant has unique needs, depending on factors such as the type of dairy products produced, the volume of production, and the specific processes involved. A reputable flooring contractor should be able to provide customized solutions tailored to your facility’s requirements.

Discuss your specific needs and challenges with the contractor and ensure they can offer a flooring solution that aligns with your goals. This may include considerations for slip resistance, impact resistance, temperature resistance, and ease of maintenance.

High-Quality Materials and Installation

The longevity and effectiveness of your dairy plant flooring depend on the quality of both the materials used and the installation process. Choose contractors who use premium-grade materials known for their durability and performance in dairy environments.

Additionally, inquire about the installation process. Ensure that the contractor employs skilled installers who follow industry best practices. Proper installation is crucial for preventing issues like cracks, uneven surfaces, and contamination points that can compromise hygiene and safety.

A Reliable Dairy Plant Flooring Contractor: Vibroser

When it comes to selecting a reliable dairy plant flooring contractor, Vibroser stands out as an industry leader. With a proven track record in dairy flooring solutions, Vibroser specializes in the installation of top-quality dairy tiles. Their expertise in dairy processing environments ensures that their dairy tile installations meet the highest standards of hygiene, durability, and safety. Vibroser’s commitment to excellence, coupled with their knowledge of specialized materials and installation techniques, makes them a trusted choice for dairy facilities looking to maintain a seamless and efficient operation. Whether it’s for new construction or renovating existing dairy flooring, Vibroser’s dedication to delivering superior dairy tile solutions ensures a pristine and productive processing environment.

What Kind of Flooring is Used in the Dairy Industry?

In the dairy industry, flooring choices are pivotal to maintaining a safe and efficient processing environment. Two common types of flooring used are dairy tile and epoxy flooring.

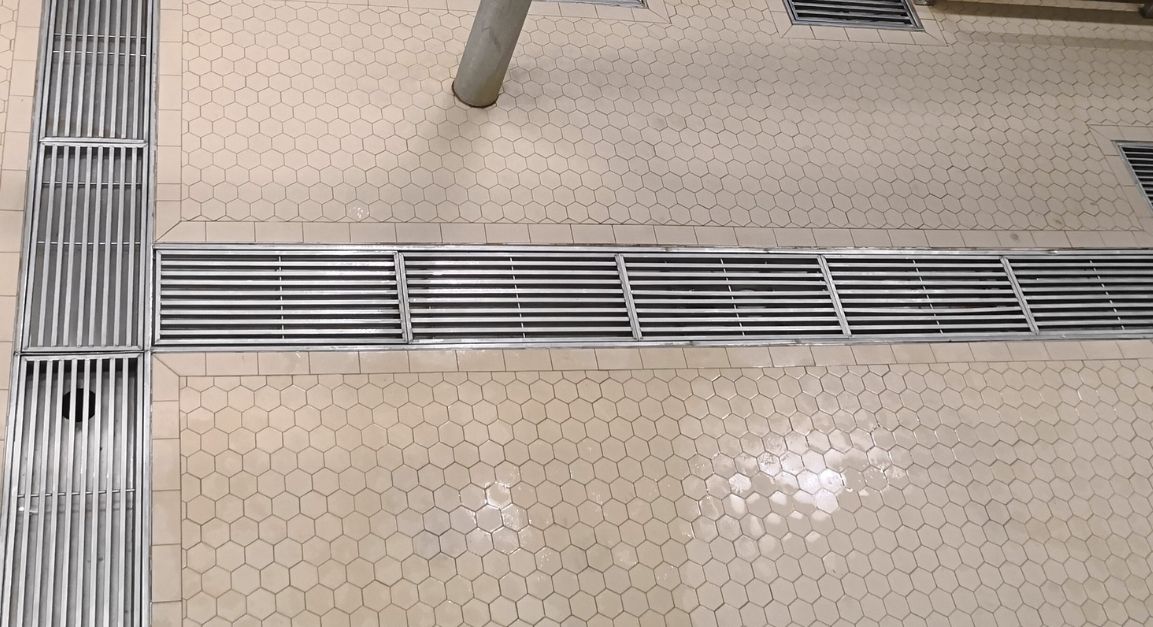

Dairy Tile Flooring: Dairy tile, also known as dairy brick or dairy tile, is a traditional and trusted flooring option. Composed of ceramic or clay tiles, it boasts a smooth, glazed surface that is easy to clean, crucial for maintaining stringent hygiene standards in dairy facilities. Dairy tiles also provide excellent resistance to moisture and chemicals, making them a durable choice. Moreover, their non-slip properties enhance safety in areas prone to spills.

Epoxy Flooring: Epoxy flooring is gaining popularity in the dairy industry due to its versatility. This seamless flooring system is made by mixing epoxy resin with hardening agents and then applying it as a liquid over the existing substrate. Once cured, epoxy forms a tough, impermeable surface that resists chemicals, moisture, and bacterial growth. Its seamless nature prevents cracks and crevices where contaminants can accumulate, ensuring a hygienic environment. Epoxy flooring also offers customizable options, including non-slip additives and various colors, to meet specific dairy facility needs.

What Type of Tile is Used in Dairy Industry?

In the dairy industry, maintaining a sterile and safe processing environment is paramount, and acid proof tiles are a commonly employed solution. These specialized tiles are typically made of materials like vitrified porcelain or high-density quarry tiles, and they are designed to withstand the harsh chemical and acidic conditions prevalent in dairy facilities.

Acid proof tiles possess excellent resistance to the corrosive properties of acids, detergents, and other harsh chemicals used during the cleaning and sanitation processes in dairy plants. This resistance ensures the longevity of the flooring while simultaneously preventing the formation of cracks or crevices where contaminants could accumulate. Moreover, acid-proof tiles often feature a textured surface to enhance slip resistance, making them a practical choice for areas prone to spills and moisture, such as processing floors and wash stations. These qualities collectively contribute to a hygienic and efficient dairy processing environment.

What is a Dairy Tile?

A dairy tile, also known as a dairy brick or milk tile, is a specialized type of flooring tile designed for use in dairy processing facilities. Typically made from materials like ceramic or clay, dairy tiles are engineered to meet stringent hygiene and durability requirements. They feature a smooth, glazed surface that is easy to clean and maintain, crucial for ensuring cleanliness in dairy environments. These tiles are also resistant to moisture and chemicals, which are prevalent in dairy operations. Dairy tiles are known for their non-slip properties, providing safety in areas susceptible to spills and ensuring a sanitary and efficient processing space for dairy products.