Food Safe Flooring: The Definitive Guide in 2024

Food safe flooring has higher standards than other industrial sectors and needs different requirements. Floor coverings with strict hygiene rules are the best floor coverings suitable for food. Finalize your choice of customized food grade floor coverings covering all light, medium, and heavy-duty sectors now and make the right choice for your project. In this guide to 2024, we’ll help you make the right choice for your food business. (We will also answer any questions you may have)

Best Flooring Material for the Food Service Industry

Floors in food enterprises must meet standards. For example, the floor should have non-slip properties, chemical resistance, and unique properties against abrasion resistance. In addition, floor coverings to be preferred in food businesses should have features that prevent the formation of fungus and mold.

Bacteria formation should be prevented in food businesses. For example, porous concrete floors cause bacterial growth. When oils and various substances penetrate the concrete floor, it can accelerate the growth of bacteria. For this purpose, food enterprises should prefer an industrial base suitable for food.

Acid Proof Tiles is a food safe flooring type that needs minor maintenance. It does not need heavy maintenance.

Choosing Hygienic Flooring for Your Food Facility in 2024

If you are planning an investment in the food sector and want it to be installed on a long-lasting floor, you should choose food safe floor coverings. Hygiene comes first in food facilities, and hygiene starts from the ground. Strict hygiene rules must be taken into account for a long-lasting food facility that meets the changing standards in 2022. In this context, floor coverings suitable for food should have the following features:

- It should be non-slip

- Unaffected by solid oils, salts (like sea salt in fish work), and cleaning chemicals

- Must be resistant to high temperatures and sudden temperature changes

- Should not produce bacteria

- It should not hold dirt

- It should not contain chemicals; it should be natural

Bacteria, molds, fungi, and other food-hazardous microorganisms can proliferate in joints, exposed joints, worn grouts, or cavities, compromising food safety. In addition, industrial floors can trap and spread odor, especially in food production facilities and catering kitchens that produce mass meals. Therefore, the right food safe floor covering should be preferred to prevent foul odors.

What is the best flooring system for a food processing facility?

There are different types of industrial floors that various organizations have approved. Although each of them has its positive features, a solution can be called the best. 2 different food safe floor coverings are most preferred worldwide: Antacid Tile Flooring and Epoxy Flooring.

Which is better, tiles or epoxy?

There are sharp differences between Antacid Tile and Epoxy Flooring. No matter what area of the food industry you are in, the priority is hygiene. Floors with hygienic values should be preferred.

Floor Slump

Resin-based epoxy floors can have varying thicknesses so that local subsidence may occur. However, a flat surface is very important since there is heavy human and vehicle traffic in food production facilities, factories, cafeterias. For this, the industrial floor should not collapse.

Acid-proof tiles are always of the same thickness and have a flat surface. As a result, antacid tile products can’t experience a problem, such as the collapse of the industrial floor.

Bacterial Growth on the Ground

Many bacteria cause foodborne infections and intoxications. The relationship between foodstuffs and microorganisms may end with hygienic floors. Since pores can form on epoxy floors, bacteria can grow and multiply rapidly in these pores. This will pose serious problems for the food produced in the facility and the ground.

Since antacid tiles are non-porous, they prevent the formation of bacteria.

Decreased Anti-Slip Value of the Floor

Epoxy floors may lose their anti-slip values at first or over time. Employees, pallet trucks, forklifts, story food carts, etc., create mobile traffic in food facilities, and there is a high risk of work accidents on a sliding floor. This risk should be minimized. This will not be possible with epoxy floor coatings.

Anti-acid tiles are produced in R9, R10, R11, and R12 classes according to CEN/TS 16165 DIN 51130 standard. The preference of antacid tiles on an industrial floor with a density of people and vehicles has become a necessity rather than a choice. Therefore, antacid tile stands out as an alternative solution for all food businesses and food factories that prioritize occupational safety.

Color Change of the Ground

In a food business, whether it is a restaurant kitchen or a dairy factory, visuality is everything, and “first sight” is an issue that should be considered in customer satisfaction. The planned / unplanned visits of the official institutions or customers that supervise the food safety, the cleanliness of the floor, its hygienic appearance, and a flat color will give the company a feeling of 100% confidence.

Unfortunately, it is a negative situation that the floor has different color tones from place to place. The color change is inevitable on polyurethane, epoxy, and resin floors. On the other hand, antacid tile does not change color for life and can be easily cleaned.

Harm to Health

Epoxy floors are produced from chemicals. Likewise, they are chemical products on polyurethane and resin floors. However, since the antacid tile is produced using natural materials, it provides hygienic floors. According to international standards, industrial antacid tile is ceramic made of raw materials pressed at high pressures.

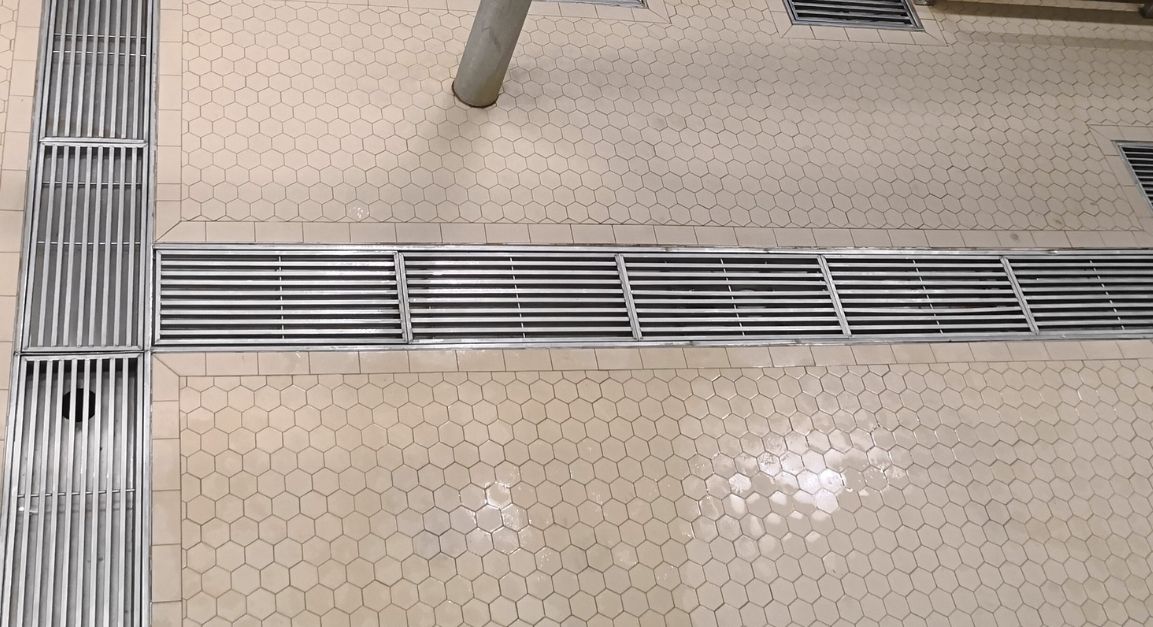

food safe flooring

Which flooring is best for industries?

In the investments to be made in the food sector, everything is on one basis: Machines, vehicles, cold rooms, storage equipment, and much more. The more solid the ground, the longer the business will last. Problems on the ground may damage the facility and cause additional costs to the investment. Renovation work on the ground may cause the plant to stop. Durable antacid flooring solutions do not require frequent repairs and do not need replacement. Thus, it provides significant cost savings. In the context of all these situations and conditions, Antacid Tile, developed by considering and testing each process, is the most powerful floor solution in the world, industrial or not. In addition, Antacid Tiles are Food-friendly Floor Coverings due to their hygienic nature.

What food business do you do? We have special solutions for you!

• Meat Processing

Those working in meat processing plants need a non-slip floor. The facility floor should be easy to clean, easily sterilized, and not affected by chemicals.

• Dairy Processing

Dairy and cheese facilities are harsh environments for industrial floors. The humidity, impact, corrosion, and thermal shock inherent in these facilities require a strong flooring solution.

• Beverage, Beer and Wine Factories

Long fermentation processes require products to stand for a long time. For this reason, floors that are not affected by weight should be preferred, where even high-tonnage products can wait for a long time. Beverage facilities need a functional and hygienic floor.

• All Food Factories

Food factories often have heavy human and vehicle traffic, which can cause floor wear over time. Therefore, industrial floors that are easy to clean and maintain should be preferred in food factories.

• Commercial Bakeries

Furnaces are areas with high temperatures. Products such as flour, sugar, salt, and spices used in production can form slippery surfaces when they contact the ground. Ovens need industrial floors resistant to high temperatures and maintain their slip-proof under all conditions.

• Commercial Kitchens

Dining halls and catering kitchens are always open to inspections by official institutions and visits to customers, and this happens frequently. Therefore, industrial flooring with an aesthetic appearance, stain resistance, and durability should be preferred in these areas.

• Restaurant and Cafe Kitchens

In restaurant and cafe kitchens, kitchen staff spends a lot of time. Since they are in constant motion, a non-slip floor type should be preferred as an industrial floor.

• Cold Storage

The floors in cold storage rooms must be resistant to cold and freezing temperatures. An industrial floor with extra resistance to chemicals in areas such as slaughterhouses should be chosen.

• Food Wholesalers

An industrial floor resistant to weights, pallet truck, and forklift movements should be preferred in wholesale food warehouses with heavy human, cargo, and vehicle traffic.

Vibroser is the Expert in Food Safe Flooring

We are far ahead of our competitors in food safe flooring coverings. We have our signature on hundreds of food factory projects worldwide. We only have high-performance industrial-grade products and application systems. We have a complete product portfolio to meet all floor and hygienic complementary product needs of our customers operating in the food sector. We can produce unique solutions in line with the conditions.

We are ready to share the knowledge, experience, and experience gained in this field.

We will provide the best solutions for your food plant. Would you like to talk to an expert now to find answers to all your questions? To do this, fill out the form below.