60 ürünler

-

Altıgen Antiasit Karo 100×116 Standart BejAltıgen Antiasit Karo 100×116 Standart Bej

Altıgen Antiasit Karo 100×116 Standart BejAltıgen Antiasit Karo 100×116 Standart Bej- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Altıgen Antiasit Karo 150×175 Standart BejAltıgen Antiasit Karo 150×175 Standart Bej

Altıgen Antiasit Karo 150×175 Standart BejAltıgen Antiasit Karo 150×175 Standart Bej- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Kilitli Antiasit Karo 100X150 Standart BejKilitli Antiasit Karo 100X150 Standart Bej

Kilitli Antiasit Karo 100X150 Standart BejKilitli Antiasit Karo 100X150 Standart Bej- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Antiasit Karo 100×200 Standart BejAntiasit Karo 100×200 Standart Bej

Antiasit Karo 100×200 Standart BejAntiasit Karo 100×200 Standart Bej- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Kilitli Antiasit Karo 150×200 Standart BejKilitli Antiasit Karo 150×200 Standart Bej

Kilitli Antiasit Karo 150×200 Standart BejKilitli Antiasit Karo 150×200 Standart Bej- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Antiasit Karo 200×200 Standart BejAntiasit Karo 200×200 Standart Bej

Antiasit Karo 200×200 Standart BejAntiasit Karo 200×200 Standart Bej- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

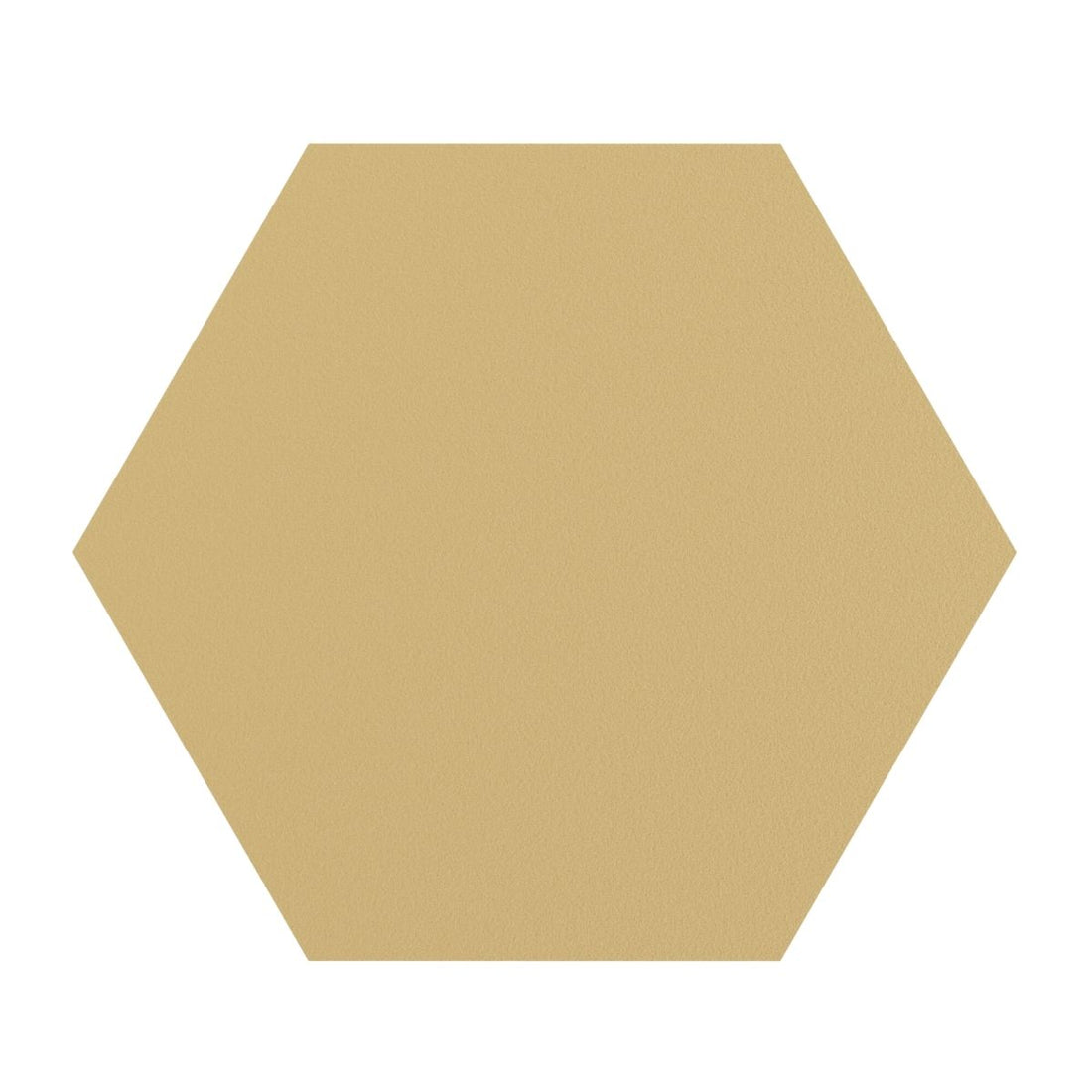

Altıgen Antiasit Karo 100×116 Hardal SarıAltıgen Antiasit Karo 100×116 Hardal Sarı

Altıgen Antiasit Karo 100×116 Hardal SarıAltıgen Antiasit Karo 100×116 Hardal Sarı- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Altıgen Antiasit Karo 100×116 Trafik SarıAltıgen Antiasit Karo 100×116 Trafik Sarı

Altıgen Antiasit Karo 100×116 Trafik SarıAltıgen Antiasit Karo 100×116 Trafik Sarı- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Altıgen Antiasit Karo 100×116 Açık GriAltıgen Antiasit Karo 100×116 Açık Gri

Altıgen Antiasit Karo 100×116 Açık GriAltıgen Antiasit Karo 100×116 Açık Gri- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Altıgen Antiasit Karo 100×116 Orta GriAltıgen Antiasit Karo 100×116 Orta Gri

Altıgen Antiasit Karo 100×116 Orta GriAltıgen Antiasit Karo 100×116 Orta Gri- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Altıgen Antiasit Karo 100×116 YeşilAltıgen Antiasit Karo 100×116 Yeşil

Altıgen Antiasit Karo 100×116 YeşilAltıgen Antiasit Karo 100×116 Yeşil- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Altıgen Antiasit Karo 100×116 MaviAltıgen Antiasit Karo 100×116 Mavi

Altıgen Antiasit Karo 100×116 MaviAltıgen Antiasit Karo 100×116 Mavi- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

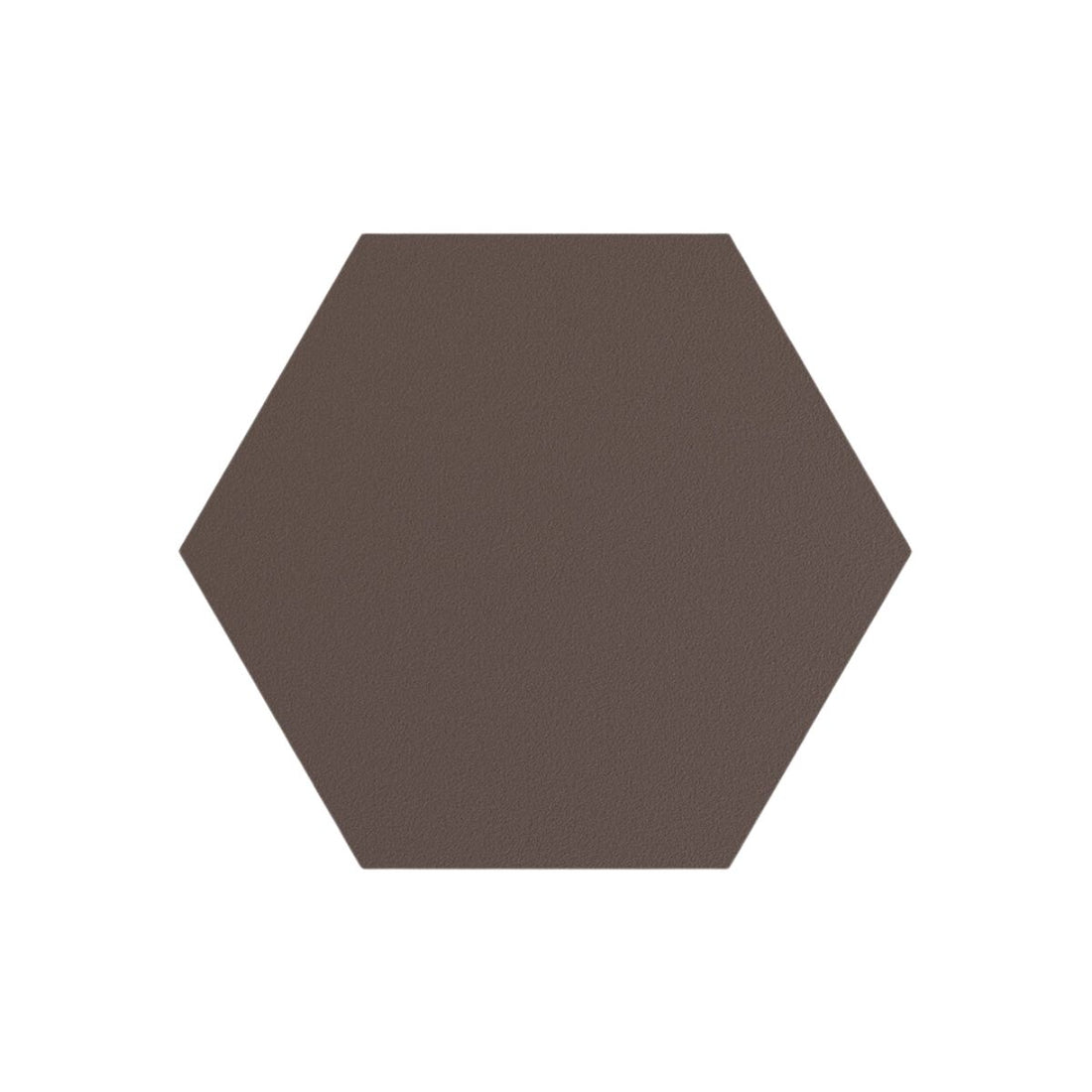

Altıgen Antiasit Karo 100×116 KahverengiAltıgen Antiasit Karo 100×116 Kahverengi

Altıgen Antiasit Karo 100×116 KahverengiAltıgen Antiasit Karo 100×116 Kahverengi- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

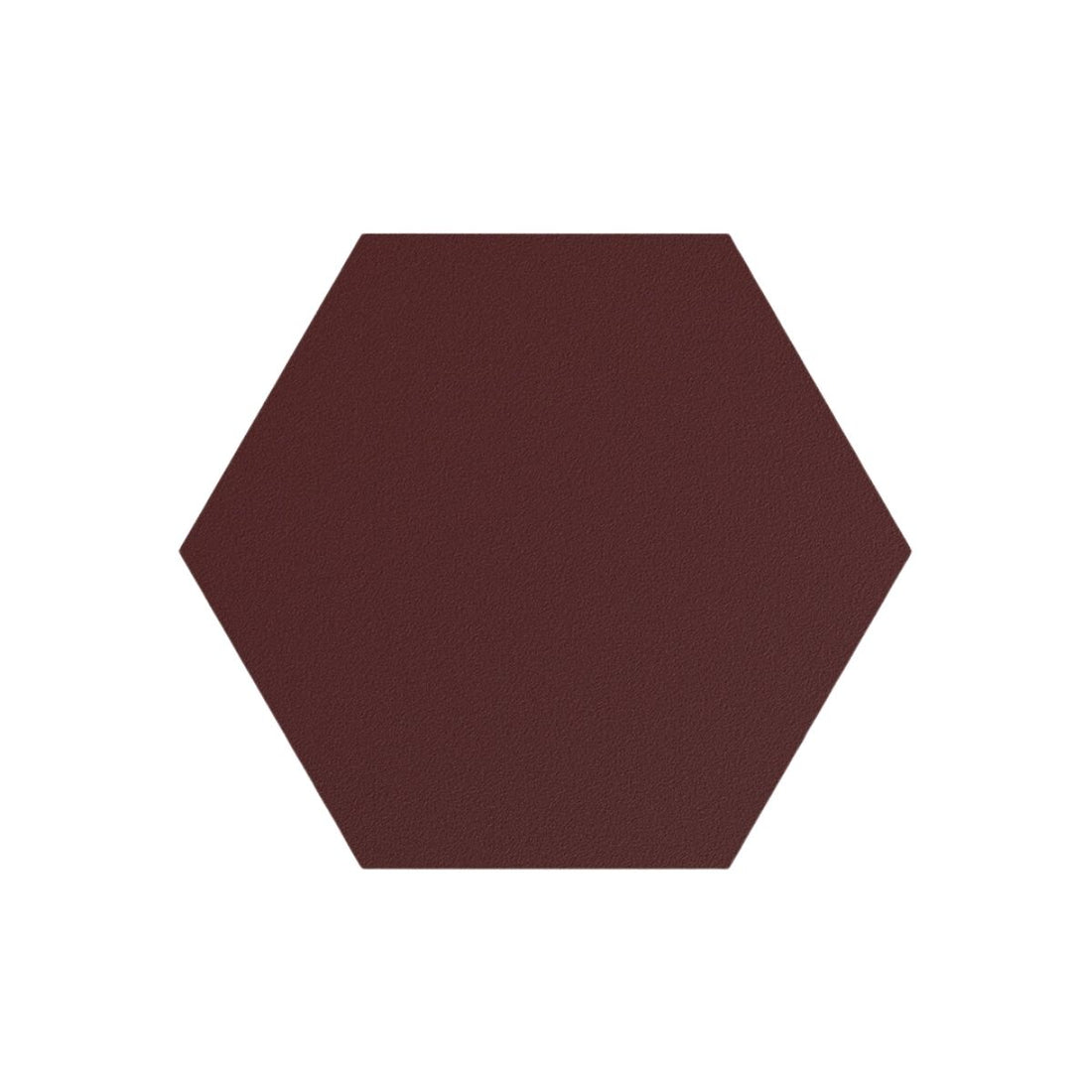

Altıgen Antiasit Karo 100×116 BordoAltıgen Antiasit Karo 100×116 Bordo

Altıgen Antiasit Karo 100×116 BordoAltıgen Antiasit Karo 100×116 Bordo- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

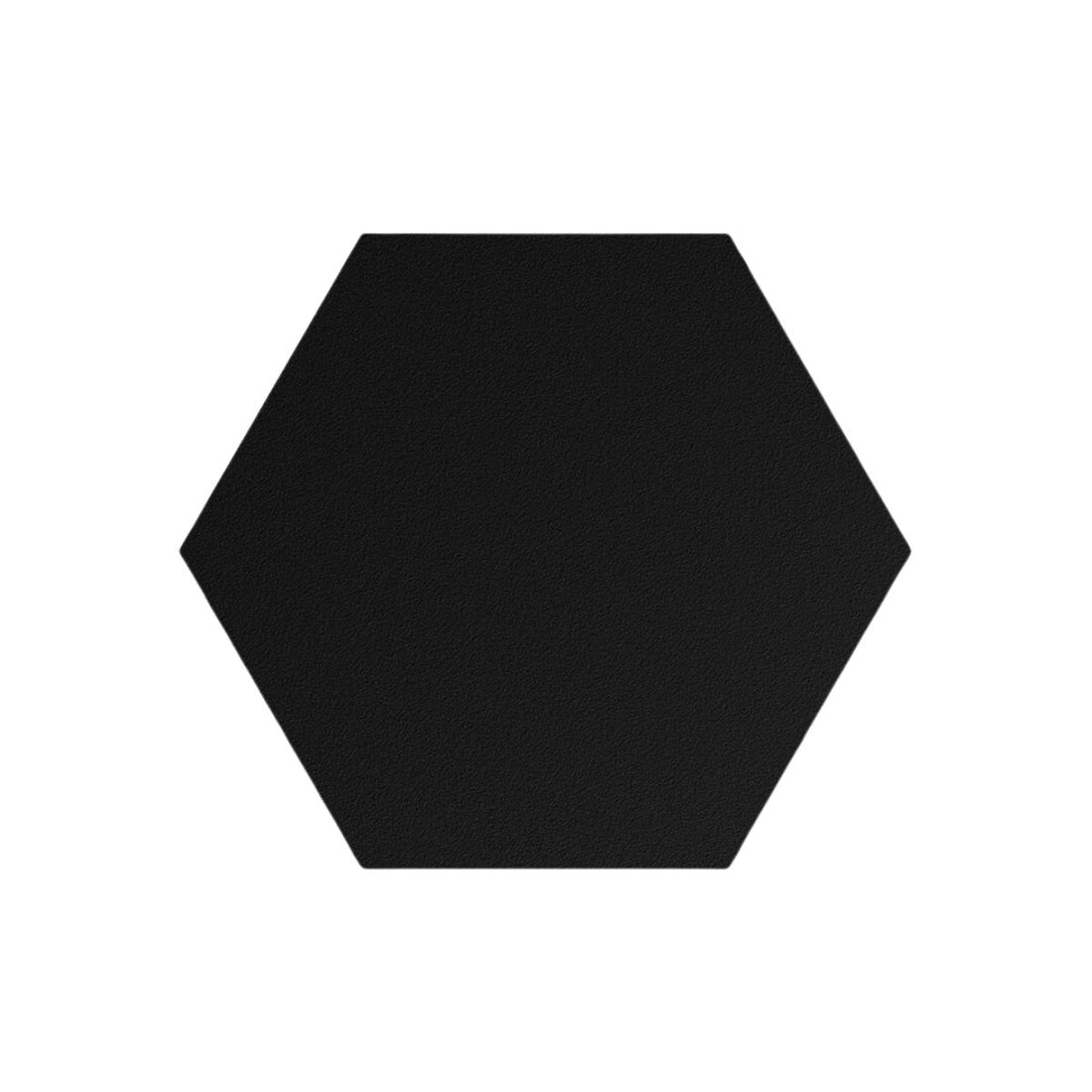

Altıgen Antiasit Karo 100×116 SiyahAltıgen Antiasit Karo 100×116 Siyah

Altıgen Antiasit Karo 100×116 SiyahAltıgen Antiasit Karo 100×116 Siyah- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Altıgen Antiasit Karo 150×175 Hardal SarıAltıgen Antiasit Karo 150×175 Hardal Sarı

Altıgen Antiasit Karo 150×175 Hardal SarıAltıgen Antiasit Karo 150×175 Hardal Sarı- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Altıgen Antiasit Karo 150×175 Trafik SarıAltıgen Antiasit Karo 150×175 Trafik Sarı

Altıgen Antiasit Karo 150×175 Trafik SarıAltıgen Antiasit Karo 150×175 Trafik Sarı- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Altıgen Antiasit Karo 150×175 Açık GriAltıgen Antiasit Karo 150×175 Açık Gri

Altıgen Antiasit Karo 150×175 Açık GriAltıgen Antiasit Karo 150×175 Açık Gri- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Altıgen Antiasit Karo 150×175 Orta GriAltıgen Antiasit Karo 150×175 Orta Gri

Altıgen Antiasit Karo 150×175 Orta GriAltıgen Antiasit Karo 150×175 Orta Gri- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Altıgen Antiasit Karo 150×175 YeşilAltıgen Antiasit Karo 150×175 Yeşil

Altıgen Antiasit Karo 150×175 YeşilAltıgen Antiasit Karo 150×175 Yeşil- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Altıgen Antiasit Karo 150×175 MaviAltıgen Antiasit Karo 150×175 Mavi

Altıgen Antiasit Karo 150×175 MaviAltıgen Antiasit Karo 150×175 Mavi- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Altıgen Antiasit Karo 150×175 KahverengiAltıgen Antiasit Karo 150×175 Kahverengi

Altıgen Antiasit Karo 150×175 KahverengiAltıgen Antiasit Karo 150×175 Kahverengi- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Altıgen Antiasit Karo 150×175 BordoAltıgen Antiasit Karo 150×175 Bordo

Altıgen Antiasit Karo 150×175 BordoAltıgen Antiasit Karo 150×175 Bordo- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Altıgen Antiasit Karo 150×175 SiyahAltıgen Antiasit Karo 150×175 Siyah

Altıgen Antiasit Karo 150×175 SiyahAltıgen Antiasit Karo 150×175 Siyah- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Kilitli Antiasit Karo 100X150 Hardal SarıKilitli Antiasit Karo 100X150 Hardal Sarı

Kilitli Antiasit Karo 100X150 Hardal SarıKilitli Antiasit Karo 100X150 Hardal Sarı- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Kilitli Antiasit Karo 100x150 Trafik SarıKilitli Antiasit Karo 100x150 Trafik Sarı

Kilitli Antiasit Karo 100x150 Trafik SarıKilitli Antiasit Karo 100x150 Trafik Sarı- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Kilitli Antiasit Karo 100x150 Açık GriKilitli Antiasit Karo 100x150 Açık Gri

Kilitli Antiasit Karo 100x150 Açık GriKilitli Antiasit Karo 100x150 Açık Gri- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Kilitli Antiasit Karo 100x150 Orta GriKilitli Antiasit Karo 100x150 Orta Gri

Kilitli Antiasit Karo 100x150 Orta GriKilitli Antiasit Karo 100x150 Orta Gri- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Kilitli Antiasit Karo 100x150 YeşilKilitli Antiasit Karo 100x150 Yeşil

Kilitli Antiasit Karo 100x150 YeşilKilitli Antiasit Karo 100x150 Yeşil- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Kilitli Antiasit Karo 100x150 MaviKilitli Antiasit Karo 100x150 Mavi

Kilitli Antiasit Karo 100x150 MaviKilitli Antiasit Karo 100x150 Mavi- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Kilitli Antiasit Karo 100x150 KahverengiKilitli Antiasit Karo 100x150 Kahverengi

Kilitli Antiasit Karo 100x150 KahverengiKilitli Antiasit Karo 100x150 Kahverengi- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Kilitli Antiasit Karo 100x150 BordoKilitli Antiasit Karo 100x150 Bordo

Kilitli Antiasit Karo 100x150 BordoKilitli Antiasit Karo 100x150 Bordo- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Kilitli Antiasit Karo 100X150 SiyahKilitli Antiasit Karo 100X150 Siyah

Kilitli Antiasit Karo 100X150 SiyahKilitli Antiasit Karo 100X150 Siyah- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Antiasit Karo 100×200 Açık GriAntiasit Karo 100×200 Açık Gri

Antiasit Karo 100×200 Açık GriAntiasit Karo 100×200 Açık Gri- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Antiasit Karo 100×200 Orta GriAntiasit Karo 100×200 Orta Gri

Antiasit Karo 100×200 Orta GriAntiasit Karo 100×200 Orta Gri- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Antiasit Karo 100×200 Hardal SarıAntiasit Karo 100×200 Hardal Sarı

Antiasit Karo 100×200 Hardal SarıAntiasit Karo 100×200 Hardal Sarı- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Antiasit Karo 100×200 Trafik SarıAntiasit Karo 100×200 Trafik Sarı

Antiasit Karo 100×200 Trafik SarıAntiasit Karo 100×200 Trafik Sarı- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Antiasit Karo 100×200 YeşilAntiasit Karo 100×200 Yeşil

Antiasit Karo 100×200 YeşilAntiasit Karo 100×200 Yeşil- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Antiasit Karo 100×200 MaviAntiasit Karo 100×200 Mavi

Antiasit Karo 100×200 MaviAntiasit Karo 100×200 Mavi- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Antiasit Karo 100×200 KahverengiAntiasit Karo 100×200 Kahverengi

Antiasit Karo 100×200 KahverengiAntiasit Karo 100×200 Kahverengi- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Antiasit Karo 100×200 BordoAntiasit Karo 100×200 Bordo

Antiasit Karo 100×200 BordoAntiasit Karo 100×200 Bordo- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Antiasit Karo 100×200 SiyahAntiasit Karo 100×200 Siyah

Antiasit Karo 100×200 SiyahAntiasit Karo 100×200 Siyah- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Kilitli Antiasit Karo 150×200 Hardal SarıKilitli Antiasit Karo 150×200 Hardal Sarı

Kilitli Antiasit Karo 150×200 Hardal SarıKilitli Antiasit Karo 150×200 Hardal Sarı- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Kilitli Antiasit Karo 150×200 Trafik SarıKilitli Antiasit Karo 150×200 Trafik Sarı

Kilitli Antiasit Karo 150×200 Trafik SarıKilitli Antiasit Karo 150×200 Trafik Sarı- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Kilitli Antiasit Karo 150×200 Açık GriKilitli Antiasit Karo 150×200 Açık Gri

Kilitli Antiasit Karo 150×200 Açık GriKilitli Antiasit Karo 150×200 Açık Gri- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Kilitli Antiasit Karo 150×200 Orta GriKilitli Antiasit Karo 150×200 Orta Gri

Kilitli Antiasit Karo 150×200 Orta GriKilitli Antiasit Karo 150×200 Orta Gri- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Kilitli Antiasit Karo 150×200 YeşilKilitli Antiasit Karo 150×200 Yeşil

Kilitli Antiasit Karo 150×200 YeşilKilitli Antiasit Karo 150×200 Yeşil- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Kilitli Antiasit Karo 150×200 MaviKilitli Antiasit Karo 150×200 Mavi

Kilitli Antiasit Karo 150×200 MaviKilitli Antiasit Karo 150×200 Mavi- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Kilitli Antiasit Karo 150×200 KahvrengiKilitli Antiasit Karo 150×200 Kahvrengi

Kilitli Antiasit Karo 150×200 KahvrengiKilitli Antiasit Karo 150×200 Kahvrengi- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Kilitli Antiasit Karo 150×200 BordoKilitli Antiasit Karo 150×200 Bordo

Kilitli Antiasit Karo 150×200 BordoKilitli Antiasit Karo 150×200 Bordo- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Kilitli Antiasit Karo 150×200 SiyahKilitli Antiasit Karo 150×200 Siyah

Kilitli Antiasit Karo 150×200 SiyahKilitli Antiasit Karo 150×200 Siyah- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Antiasit Karo 200×200 Hardal SarıAntiasit Karo 200×200 Hardal Sarı

Antiasit Karo 200×200 Hardal SarıAntiasit Karo 200×200 Hardal Sarı- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Antiasit Karo 200×200 Trafik SarıAntiasit Karo 200×200 Trafik Sarı

Antiasit Karo 200×200 Trafik SarıAntiasit Karo 200×200 Trafik Sarı- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Antiasit Karo 200×200 Açık GriAntiasit Karo 200×200 Açık Gri

Antiasit Karo 200×200 Açık GriAntiasit Karo 200×200 Açık Gri- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Antiasit Karo 200×200 Orta GriAntiasit Karo 200×200 Orta Gri

Antiasit Karo 200×200 Orta GriAntiasit Karo 200×200 Orta Gri- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Antiasit Karo 200×200 YeşilAntiasit Karo 200×200 Yeşil

Antiasit Karo 200×200 YeşilAntiasit Karo 200×200 Yeşil- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Antiasit Karo 200×200 MaviAntiasit Karo 200×200 Mavi

Antiasit Karo 200×200 MaviAntiasit Karo 200×200 Mavi- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Antiasit Karo 200×200 KahverengiAntiasit Karo 200×200 Kahverengi

Antiasit Karo 200×200 KahverengiAntiasit Karo 200×200 Kahverengi- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Antiasit Karo 200×200 BordoAntiasit Karo 200×200 Bordo

Antiasit Karo 200×200 BordoAntiasit Karo 200×200 Bordo- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

-

Antiasit Karo 200×200 SiyahAntiasit Karo 200×200 Siyah

Antiasit Karo 200×200 SiyahAntiasit Karo 200×200 Siyah- Normal fiyat

-

0.00TL - Normal fiyat

-

- Satış fiyatı

-

0.00TL

Antiasit seramik karo; asitlere, bazlara, alkaliye, solventlere ve diğer kimyasallara karşı dirençli yapıya sahip, endüstriyel zemin kaplama ürünüdür. Özellikle antibakteriyel özellikleri ve asitlere karşı dayanıklı olması nedeniyle; gıda sektörü zeminlerinde, endüstriyel ortamlarda, laboratuvarlarda, kimyasal işlemlerin yapıldığı alanlarda veya asit içeren temizlik maddelerinin sıkça kullanıldığı tesisler için idealdir.

Aside dayanıklı seramik karo; asitlere, bazlara ve diğer kimyasallara karşı dayanıklı bir yüzeye sahiptir. Kimyasal etkilere maruz kaldığında renk solması veya yüzey hasarı gibi deformasyonları olmaz. Yüksek sıcaklıklara dayanıklıdır ve aşındırıcı maddelere karşı direnç gösterir. Ayrıca, hijyenik özelliklere sahiptir ve kolay temizlenebilir.

Antiasit seramik karolar, farklı boyutlarda, desenlerde ve renklerde bulunabilir, bu da tasarım ve dekorasyon açısından çeşitlilik sağlar. Kullanılacak alana ve tercihlere bağlı olarak, uygun antiasit seramik karolar seçilmelidir.

Kimyasallara Dayanıklı Antiasit Seramik Özellikleri

Kimyasallara dayanıklı antiasit seramik karoların özellikleri, karoların farklı sektörlerde talep edilmesini sağlar. Pek çok zeminde mükemmel performans sağlayan antiasit seramik karoların genel özellikleri şu şekildedir:

- Mat bir yüzeye sahiptir. Bu sayede kayma ve aşınmaya neden olmaz. Güvenli ve konforlu bir kullanım sunar.

- Ağır maddelere karşı son derece dayanıklıdır. Yüksek kırılma mukavemeti sayesinde pek çok zeminde kaliteli bir kullanımı olanaklı kılar.

- Asit, yağ çözücü başta olmak üzere pek çok kimyasal karşı yüksek dayanıklılık gösterir.

- Standart bir boyutta üretilebildiği gibi özel boyutlarda üretimi de mümkündür.

- Aşırı gerilim ve yüklere bile dayanma gücüne sahiptir.

- Zeminin dayanıklı ve kaliteli olmasına katkıda bulunduğu için iş güvenliğini sağlar.

- Su geçirmez özelliği ile sızdırmazlığına olanak tanır.

- Leke tutmaz ve kolay temizlenir özelliği, zeminin hijyenik bir form elde etmesini sağlar.

- Kaymaz özelliği sayesinde olası iş kazalarının önüne geçer.

Uzun bir kullanım süresine sahip olan antiasit seramik karolar hijyenik özelliği sayesinde düşük bakım maliyetleri imkanı sağlar. Zamandan ve maliyetten tasarruf sağlayan endüstriyel karolar, estetik ve zarif bir görünüme de sahiptir.

Kaymaz ve Aşınmaz Özellikteki Seramiklerin Kullanım Alanları

Kaymaz ve aşınmaz özellikteki seramiklerin kullanım alanları bir hayli geniştir. Birçok sektörde kullanılmakla birlikte daha çok gıda fabrikaları, et ve süt tesisleri, balıkhaneler başta olmak üzere hijyenin önemli bir kriter olduğu alanlarda tercih edilir. Gıda üretiminin yapıldığı alanlarda tercih edilen zemin döşeme ürünlerinden biri olan antiasit seramik, iş güvenliği ve hijyeni koruma noktasında son derece başarılıdır.

Bu tür alanlarda daha çok antiasit seramik karo ve altıgen antiasit karo kullanılır. Gıda üretiminin gerçekleştiği alanlarda, işlemlerin yapılabilmesi adına farklı özellikte ve ağırlıkta makineler tercih edilir. Bu tür ağır makinelere dayanıklı olan zemin döşemeleri, zemin güvenliğinin sağlanabilmesi açısından çok önemlidir. Bunun yanı sıra kullanılan kimyasallar, zeminde deformasyona neden olabilir. Kaliteli, dayanıklı seramikler; zeminin kimyasallardan etkilenmemesini sağlar.

Yenilikçi tasarımlarıyla ön plana çıkan antiasit seramikler gıda üretim tesislerinin yanı sıra genel olarak şu alanlarda tercih edilir:

- Et entegre tesislerinde,

- Tavuk tesislerinde,

- Balık tesislerinde,

- Süt ve süt ürünleri tesislerinde,

- Fırınlarda, pastanelerde,

- Toplu yemek üretim yerlerinde,

- Bitkisel ve hayvansal yağ üretim fabrikalarında,

- Otomotiv sektöründeki üretim tesislerinde,

- Araç servisleri ve showroomlarda,

- Tekstil sektöründe,

- Kimya sektöründe,

- Kozmetik sektöründe,

- Alışveriş merkezlerinde, süpermarketler ve yapı marketlerde,

- Sağlık sektöründeki hastanelerde, laboratuvarlarda, ilaç fabrikalarında, ilaç depolarında,

- Ulaşım sektöründeki otobüs terminallerinde, metro istasyonlarında ve havaalanlarında,

- Enerji santrallerinde,

- Turizm sektöründe

Birçok farklı alanda ihtiyaçları karşılayan endüstriyel seramikler, ilgili alanda zemin özelliklerine göre üretilir. Her zeminin gereksinimleri birbirinden farklıdır. Bazı tesislerde zeminin, ağır araçlara ve makinelere karşı yüksek mukavemet göstermesi gerekir. Bunun yanı sıra bazı zeminlerin korozyona karşı dayanıklı olması talep edilir. Bu nedenle zeminin özellikleri detaylı bir şekilde incelendikten sonra, zemin için en uygun çözüme ulaşılır.

Hijyenik Bir Zemin Sağlayan Antiasit Seramik Karo Avantajları

Hijyenik bir zemin sağlayan antiasit seramik avantajları, ürünün konforlu bir şekilde kullanılmasını sağlar. İş güvenliği kurallarına uygun bir şekilde döşeme uygulanması, iş kazalarını önleyeceğinden, kullanılacak döşeme ürününün avantajları oldukça önemlidir. Antiasit karo avantajları şu şekildedir:

- Zararlı kimyasalların olumsuz etkileri engellenir.

- Boyut ve formu, ağır yükler ve darbelere karşı zeminin korunmasını sağlar.

- Gözeneksiz yapısı, sıvı sızıntılarını önler.

- Düzenli bakımı gerektirmeyen bir yapıya sahiptir. Bu sayede bakım masrafları minimuma indirilir.

- Çizilmeye karşı dirençlidir. Bu durum, estetik ve şık yapısının korunmasını sağlar.

- Farklı renk seçenekleriyle zeminin eşsiz bir görünüm elde etmesini sağlar.

Yüksek Kırılma Mukavemetine Sahip Antiasit Seramik Çeşitleri

Yüksek kırılma mukavemetine sahip antiasit seramik çeşitleri, farklı ortamların gereksinimlerini karşılayabilecek özelliktedir. Gri, bej, sarı olmak üzere farklı renk seçenekleri bulunan altıgen antiasit karo; arkası yapışma mukavemetini arttırıcı özelliğe sahiptir. Bununla birlikte yüzey kaymazlığı R9, R10, R11 ve R12 sınıflarındadır. Bu sayede yüzeyin kayma gibi sorunlara karşı korunmasını sağlar.

Hem kaliteli hem de estetik bir kullanım sunan bu tür karolar, kolay temizlenebilir bir yapıdadır. Düzenli aralıklarla temizlenmesi olanaklıdır. Özellikle gıda üretiminin yapıldığı alanlarda, zemin hijyenik ve temiz kalır. Antiasit seramik kategorisinde yer alan antiasit karo, oldukça fonksiyonel bir kullanım sağlayan bir döşeme çözümüdür. Antibakteriyel özelliği, zemin üzerinde kir ve bakteri birikmesini önler. Bunun yanı sıra eğilme, bükülme gibi deformasyonlara karşı son derece dayanıklıdır.

Antiasit Seramik Satın Almadan Önce Dikkat Edilmesi Gerekenler

Antiasit seramik satın almadan önce dikkat edilmesi gerekenler, kaliteli ve yenilikçi ürünlerin satın alınmasını ve bu ürünlerin zemin üzerinde kullanılmasını sağlar. Hijyenik, kir tutmayan antiasit seramiklerin satın alımı öncesinde dikkat edilmesi gerekli olan hususlar şu şekildedir:

- Ortama en uygun ürünler tercih edilmelidir. Ürünlerin boyutları, zemin gereksinimlerini karşılayabilecek düzeyde olmalıdır.

- Ürünlerin her biri, kalite standartlarında olmalıdır. Bu sayede hem uzun süre kullanılır hem de kullanım sırasında herhangi bir soruna neden olmaz.

- Yüksek kırılma mukavemetine sahip olmalıdır. Ağır makine ve yüklerin taşınması sırasında kırılmamalı, herhangi bir şekilde zarar görmemelidir.

- Kaymaz özellikte olmalıdır. İş güvenliğini sağlama noktasında kaymaz zemin tercih edilmelidir.

Fiyat-performans ürünü olan antiasit seramik karoların kalitesi, zeminler için uzun ömürlü çözümdür.

Vibroser, endüstriyel zemin kaplama çözümleriyle geniş ürün seçeneğine sahiptir. Vibroser’in ürünlerini inceleyebilir, daha fazla bilgi için iletişime geçebilirsiniz.

Antiasit karo nedir?

Antiasit karo, kimyasallara, özellikle de asitlere karşı yüksek direnç gösteren özel seramik veya porselen karolardır. Bu karolar, agresif kimyasal ortamlara dayanıklı olmaları sayesinde endüstriyel tesislerde, laboratuvarlarda, gıda üretim alanlarında ve kimyasal tesislerde yaygın olarak kullanılır. Özellikle kimyasal laboratuvarlar, endüstriyel tesisler, kimyasal depolar, atık su arıtma tesisleri gibi asit içeren ortamlarda kullanılır.

Antiasit seramik ne demek?

Antiasit seramik, asitlere, kimyasal reaktif maddelere ve agresif kimyasallara karşı dayanıklılık sağlayan endüstriyel zemin kaplama ürünüdür.