9 products

-

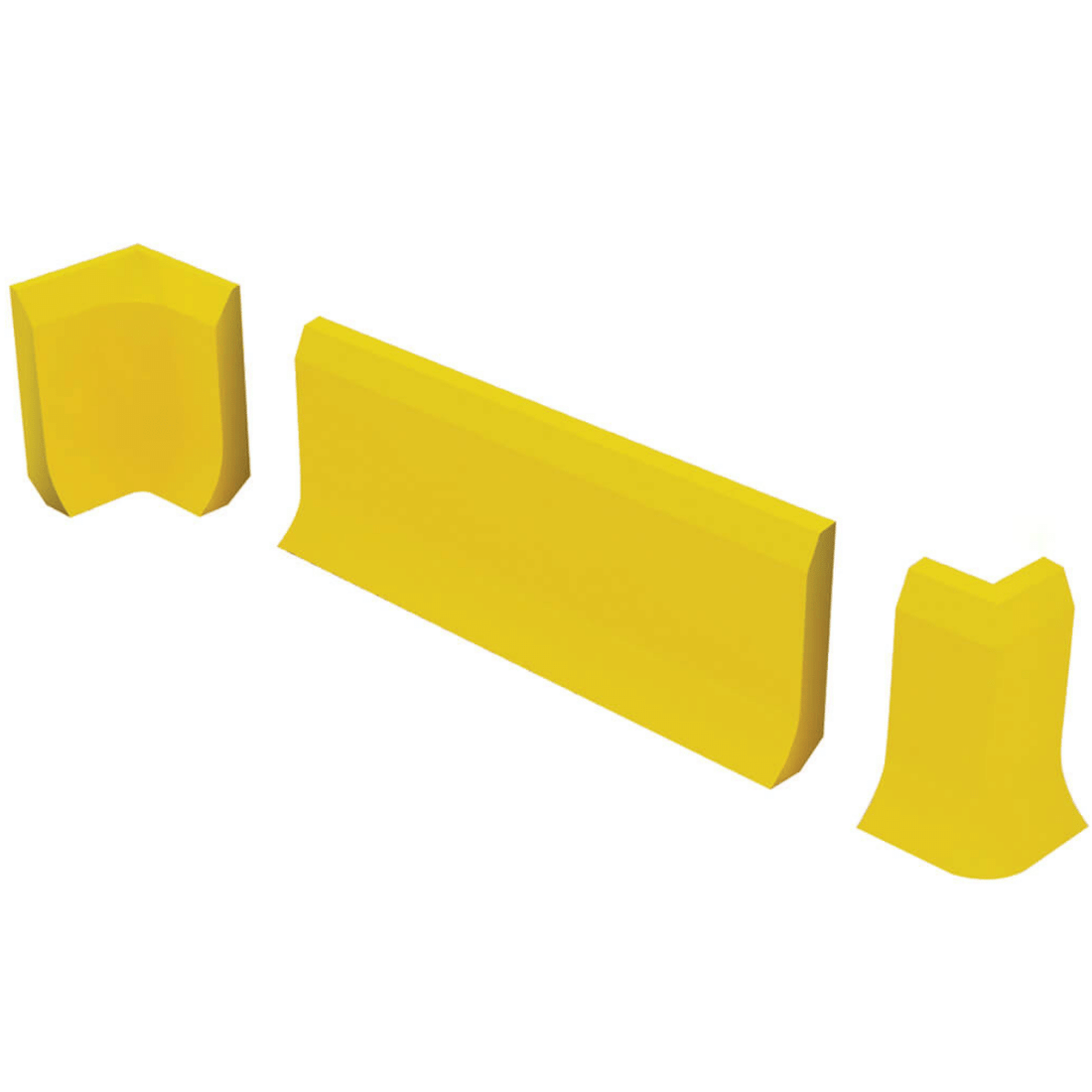

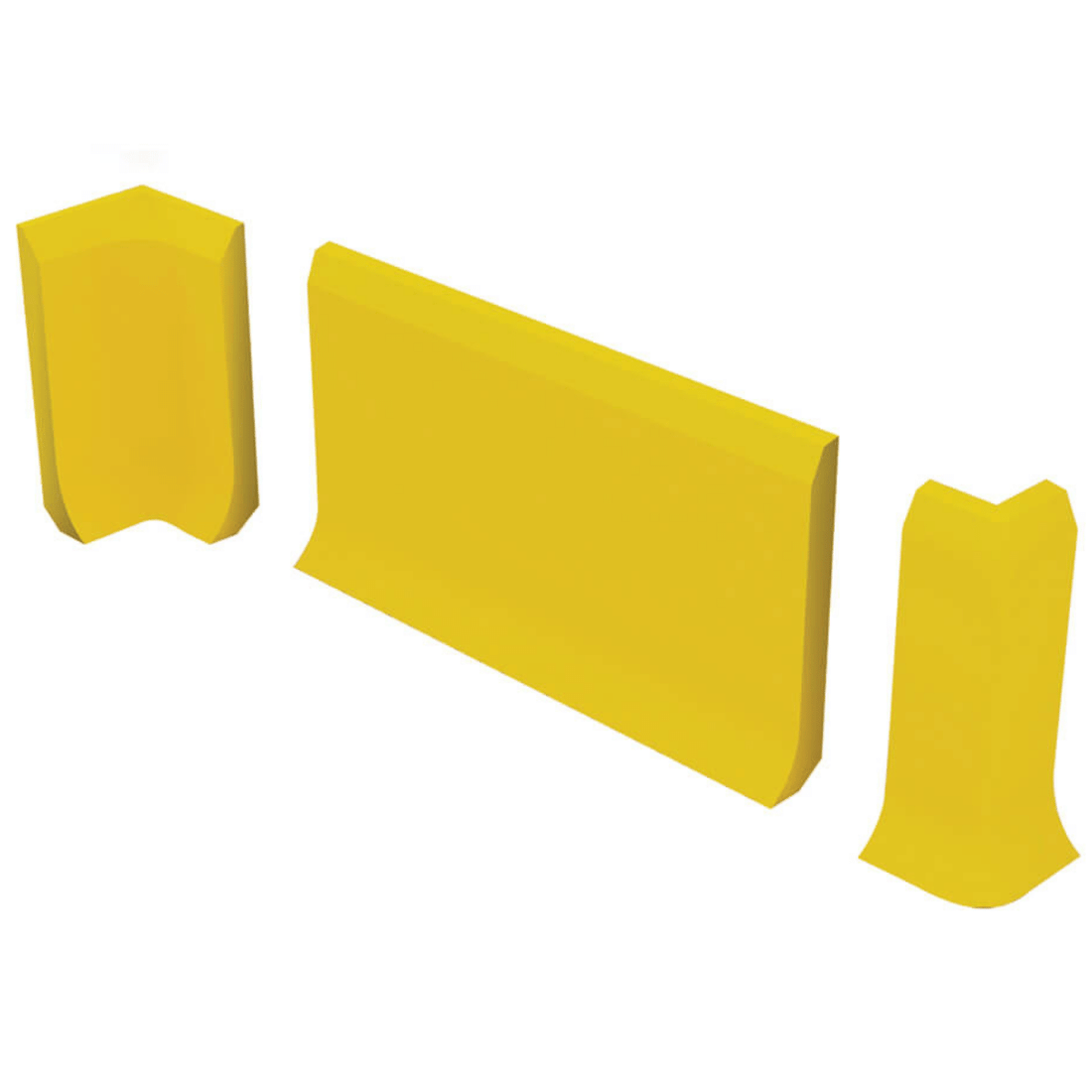

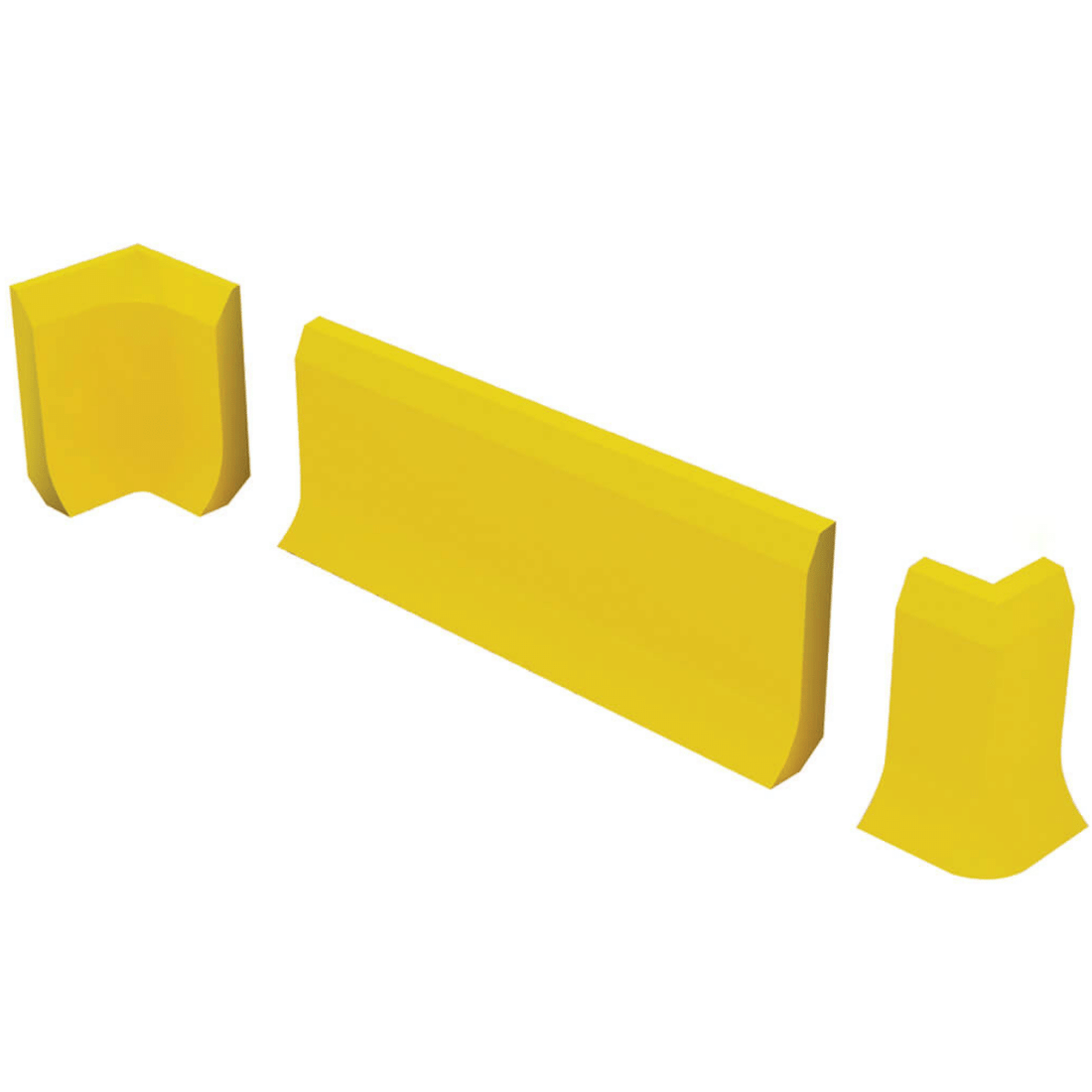

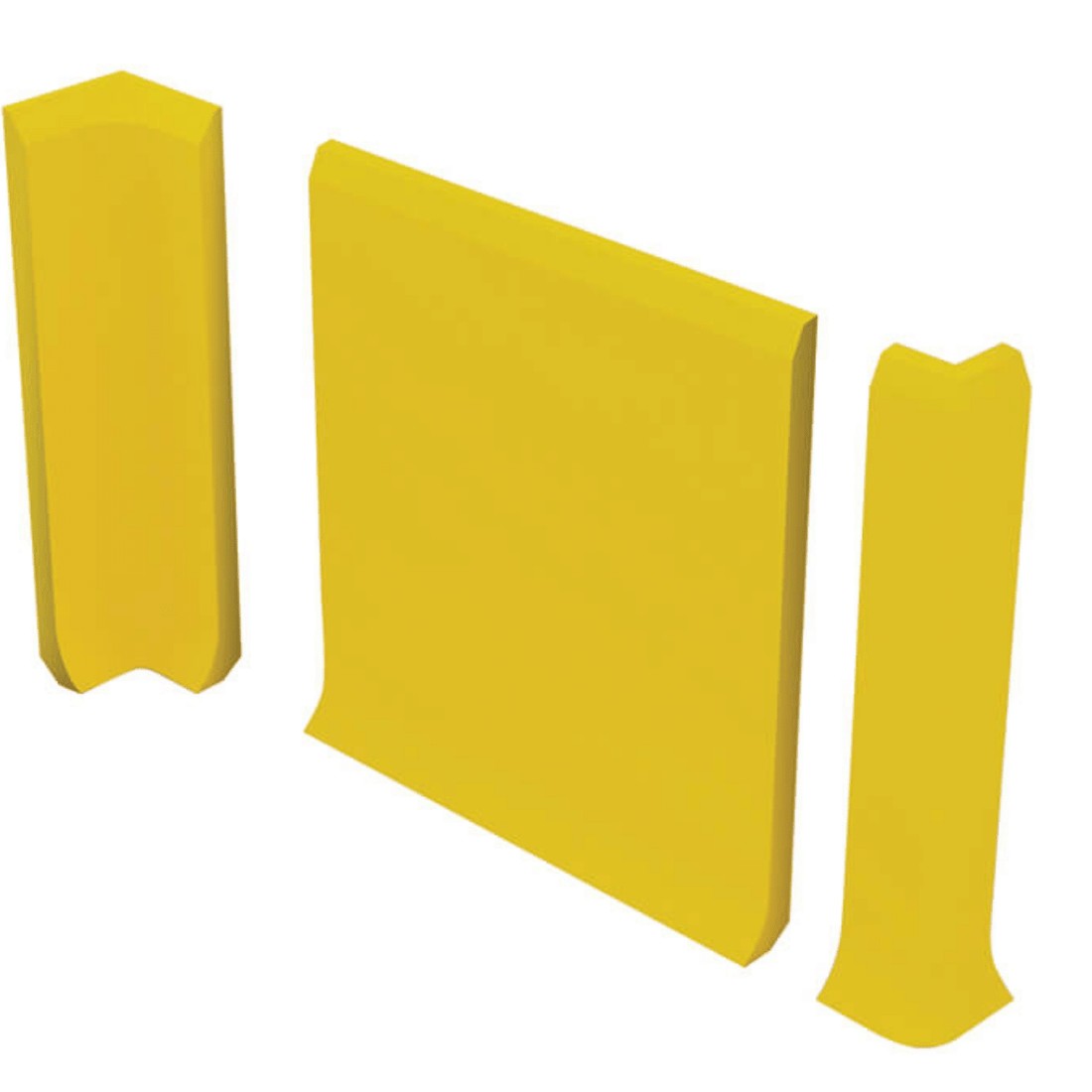

Hygienic Skirting, On Top of the Floor Covering 100x1000x10mmHygienic Skirting, On Top of the Floor Covering 100x1000x10mm

Hygienic Skirting, On Top of the Floor Covering 100x1000x10mmHygienic Skirting, On Top of the Floor Covering 100x1000x10mm- Regular price

-

0.00TL - Regular price

-

- Sale price

-

0.00TL

-

Hygienic Skirting, On Top of the Floor Covering 150x1000x12mmHygienic Skirting, On Top of the Floor Covering 150x1000x12mm

Hygienic Skirting, On Top of the Floor Covering 150x1000x12mmHygienic Skirting, On Top of the Floor Covering 150x1000x12mm- Regular price

-

0.00TL - Regular price

-

- Sale price

-

0.00TL

-

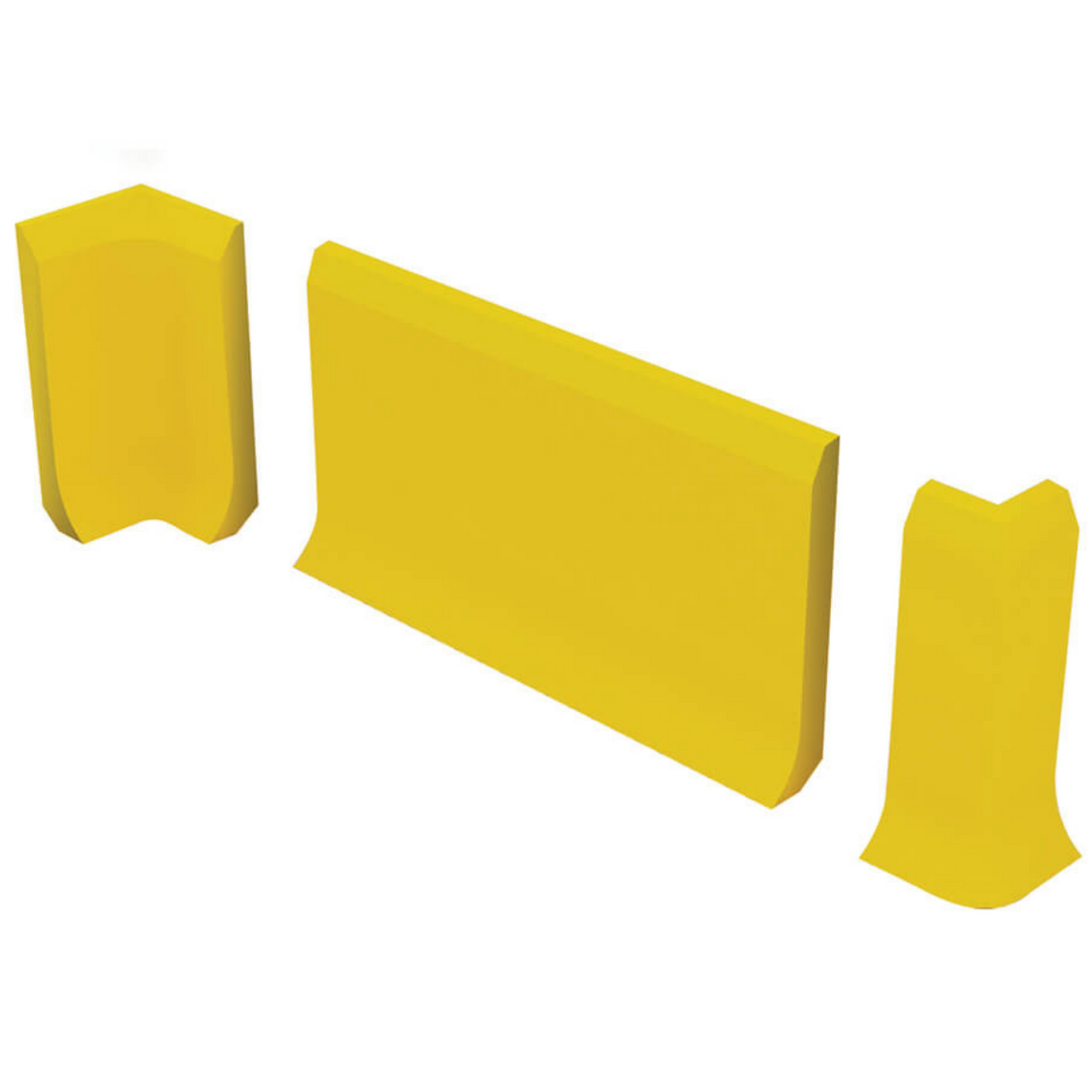

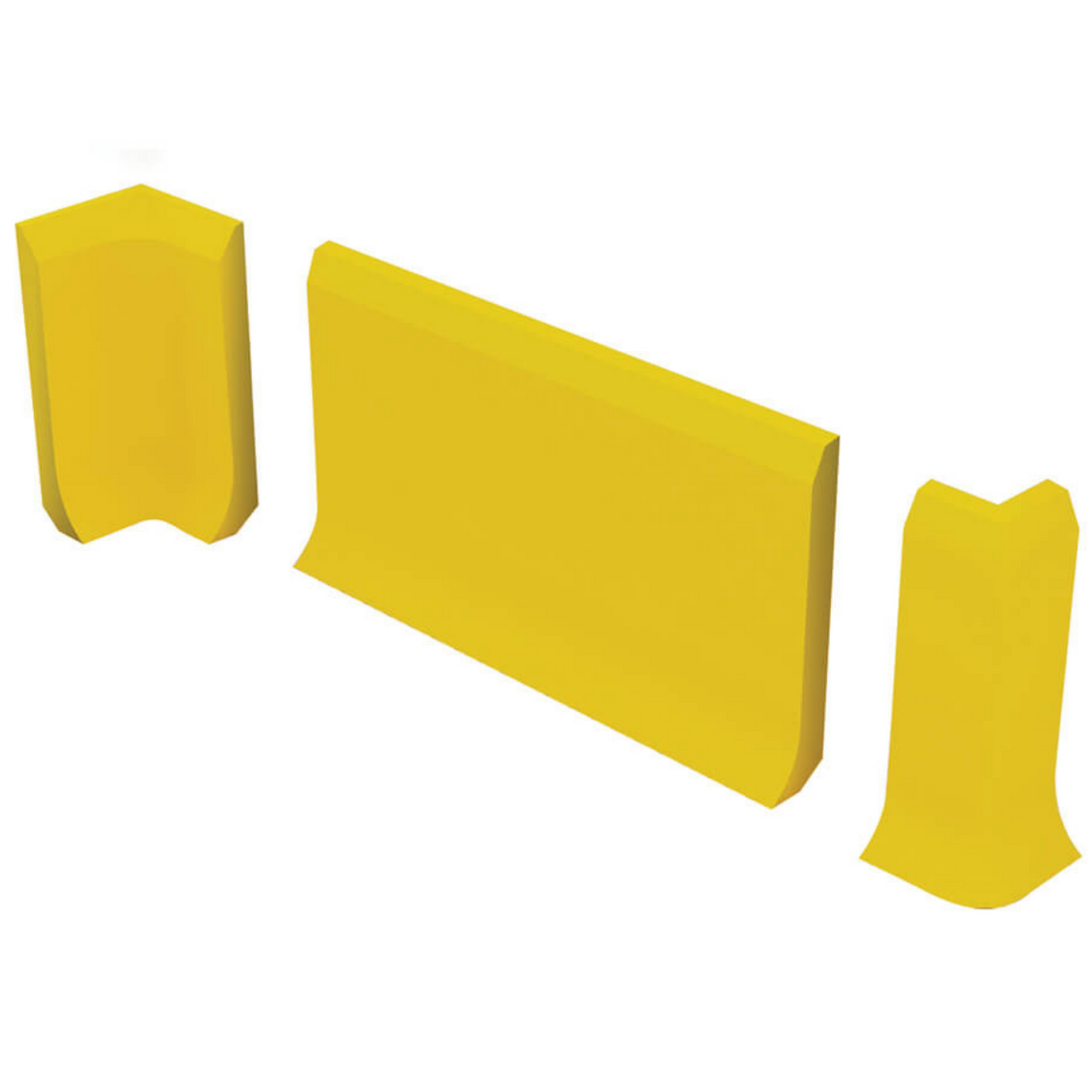

Hygienic Skirting, On Top of the Floor Covering 300x750x15mmHygienic Skirting, On Top of the Floor Covering 300x750x15mm

Hygienic Skirting, On Top of the Floor Covering 300x750x15mmHygienic Skirting, On Top of the Floor Covering 300x750x15mm- Regular price

-

0.00TL - Regular price

-

- Sale price

-

0.00TL

-

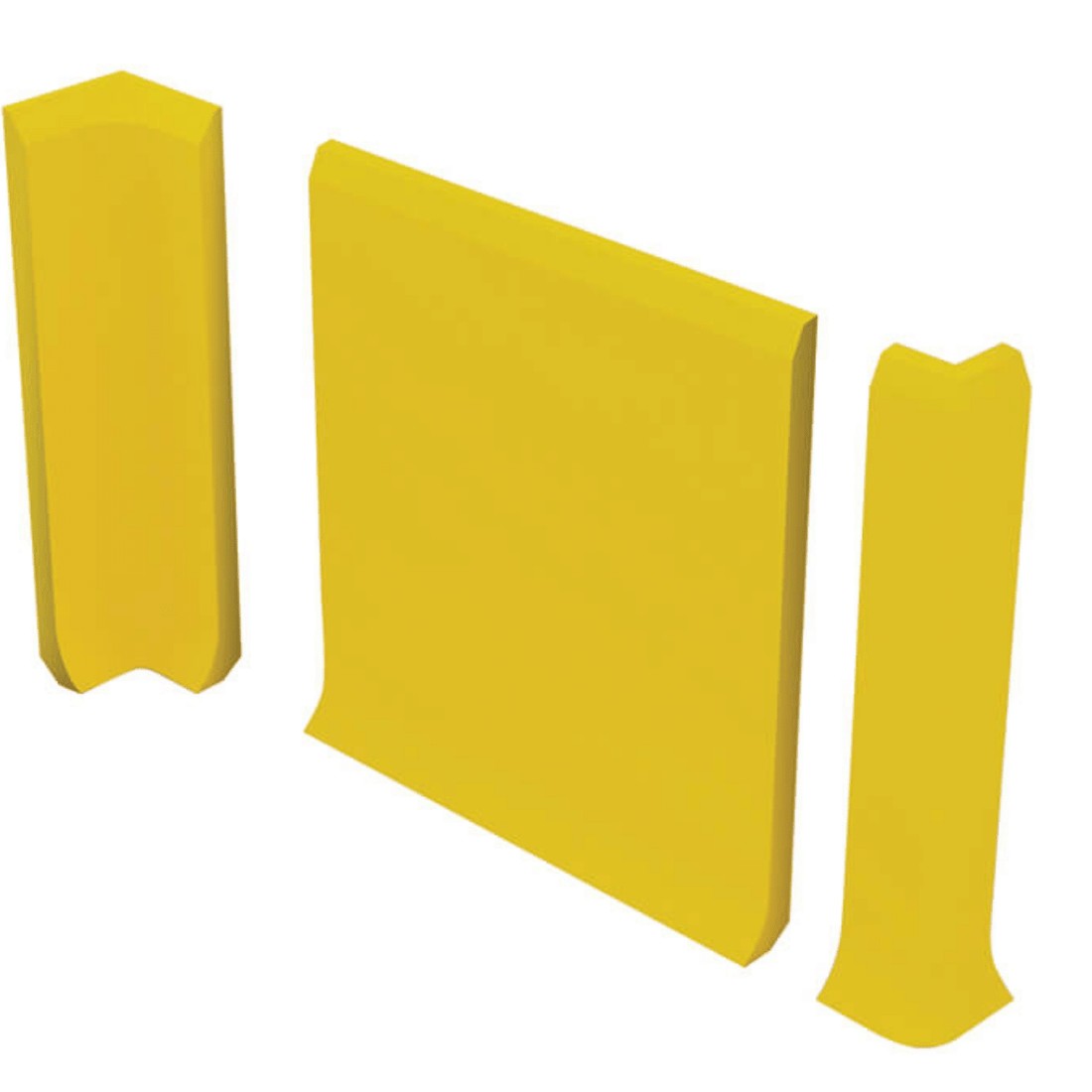

Hygienic Skirting, On Top of the Floor Covering 1000x750x15mmHygienic Skirting, On Top of the Floor Covering 1000x750x15mm

Hygienic Skirting, On Top of the Floor Covering 1000x750x15mmHygienic Skirting, On Top of the Floor Covering 1000x750x15mm- Regular price

-

0.00TL - Regular price

-

- Sale price

-

0.00TL

-

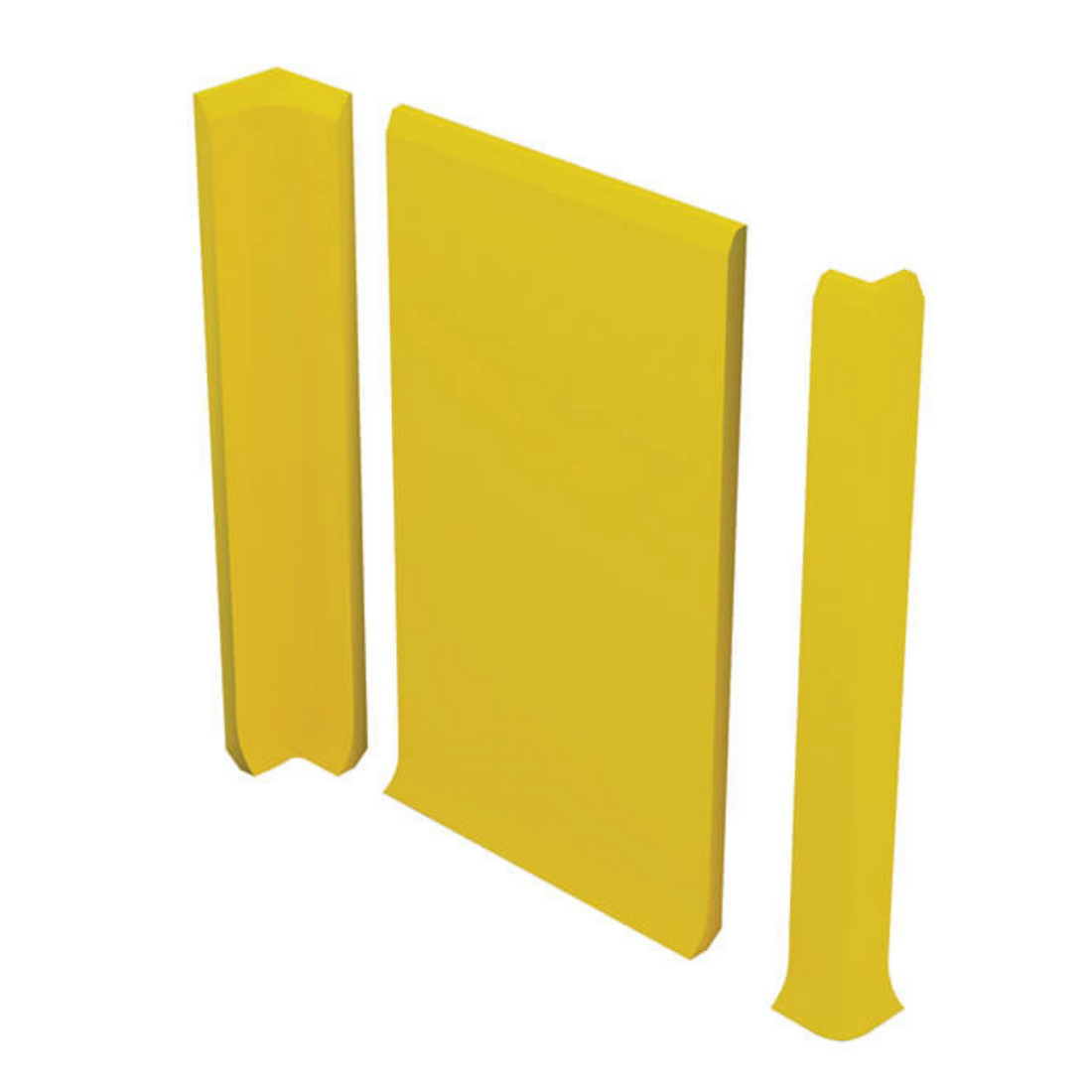

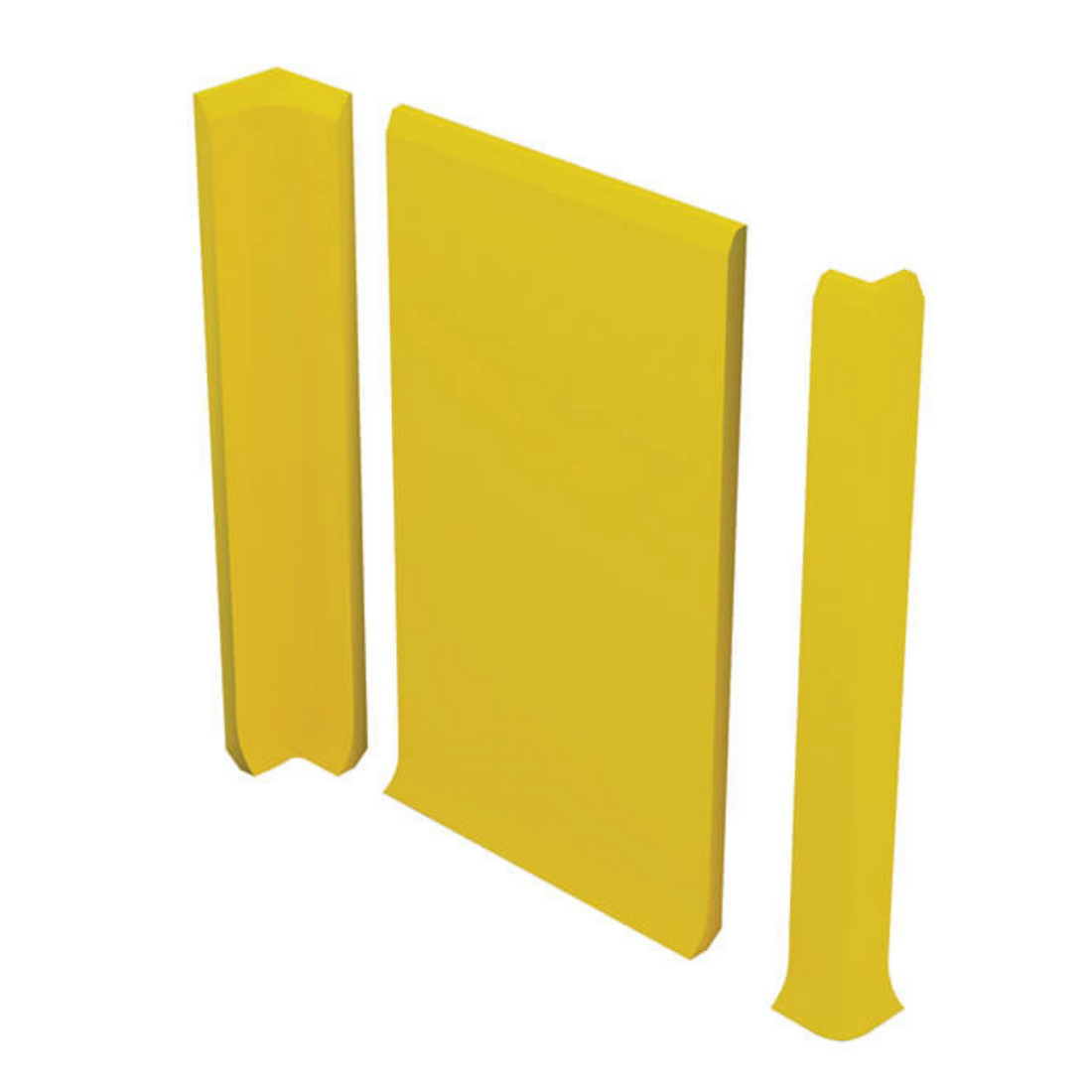

Hygienic Skirting, Flooring Edge 165x1000x13mmHygienic Skirting, Flooring Edge 165x1000x13mm

Hygienic Skirting, Flooring Edge 165x1000x13mmHygienic Skirting, Flooring Edge 165x1000x13mm- Regular price

-

0.00TL - Regular price

-

- Sale price

-

0.00TL

-

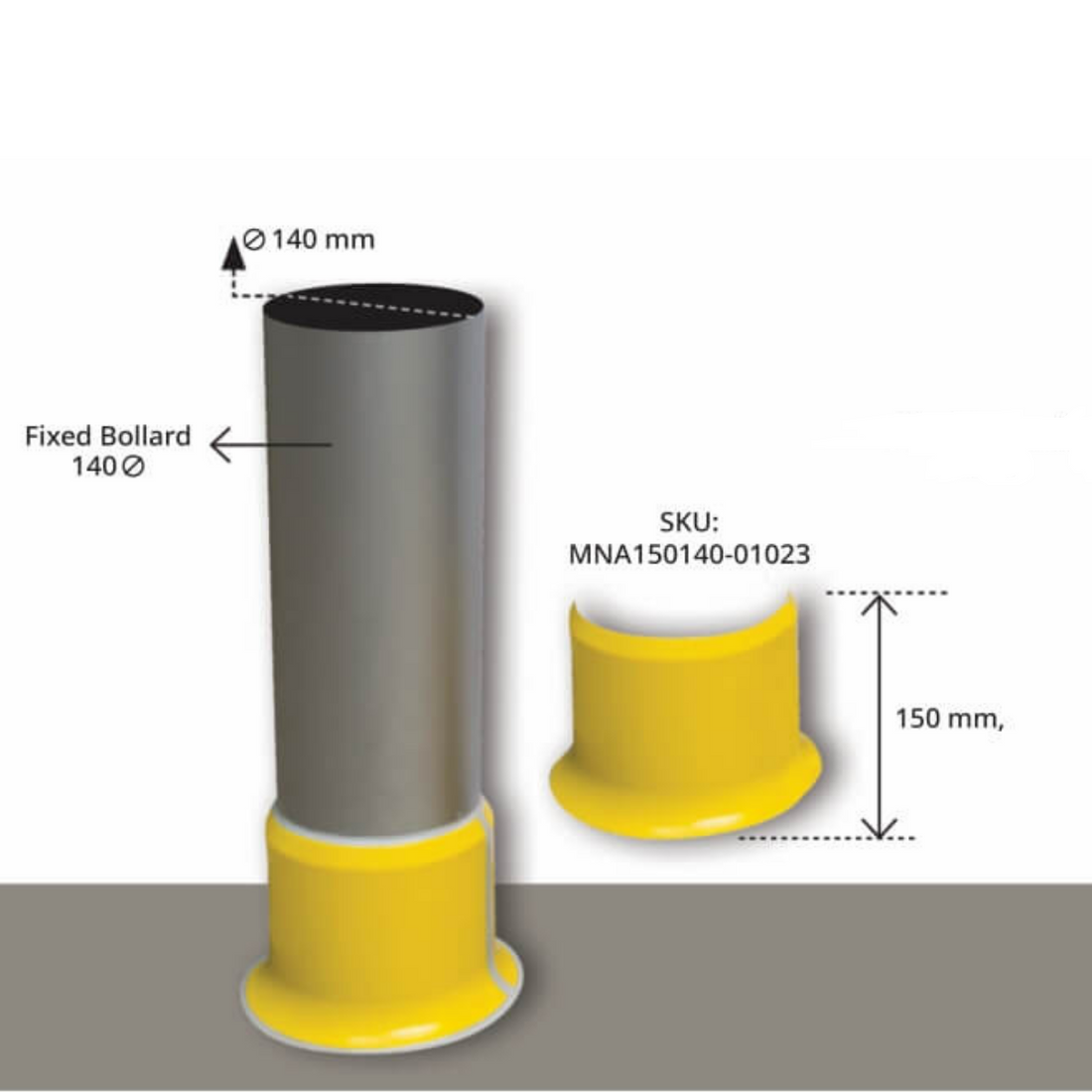

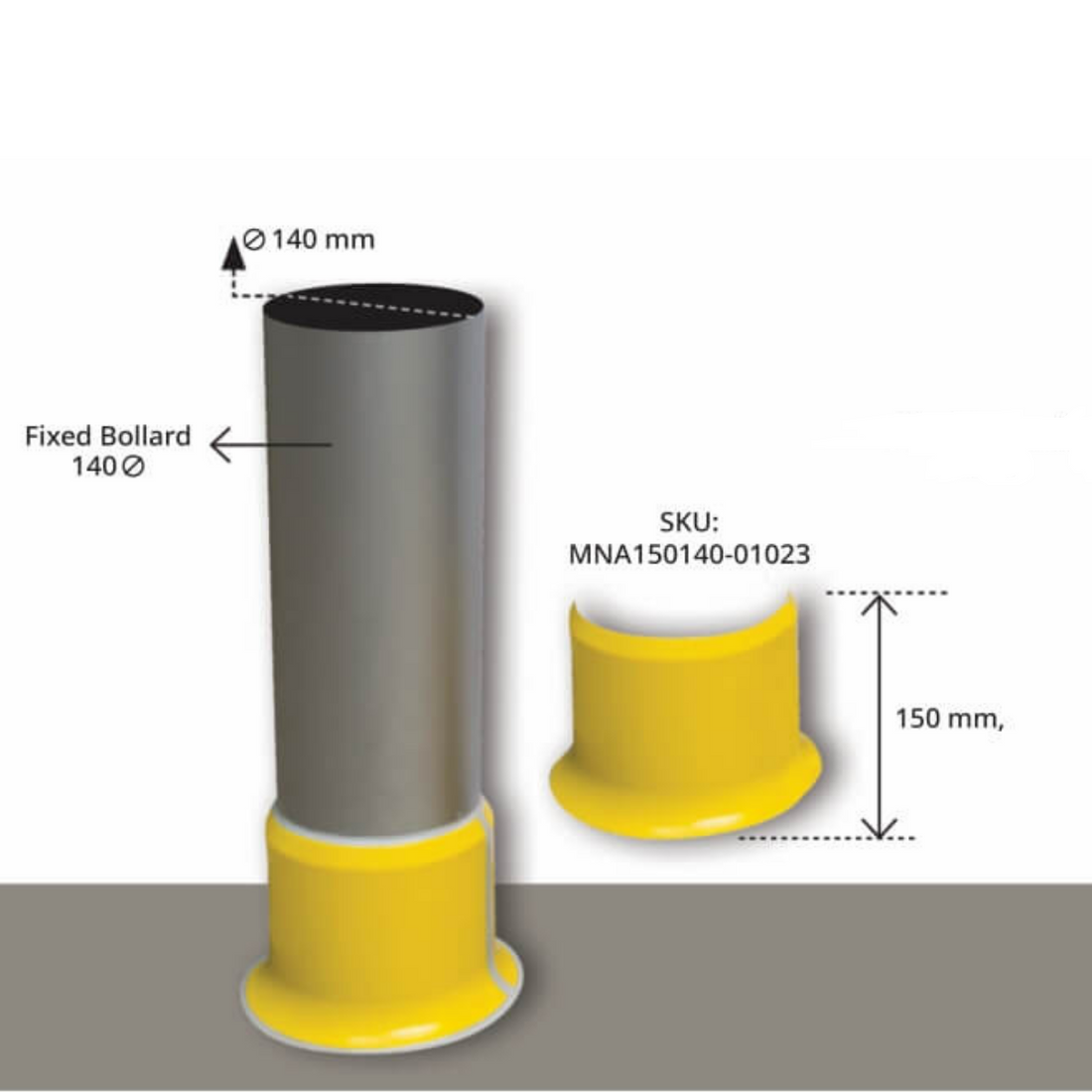

Hygienic Column Skirting 150x140mmHygienic Column Skirting 150x140mm

Hygienic Column Skirting 150x140mmHygienic Column Skirting 150x140mm- Regular price

-

0.00TL - Regular price

-

- Sale price

-

0.00TL

-

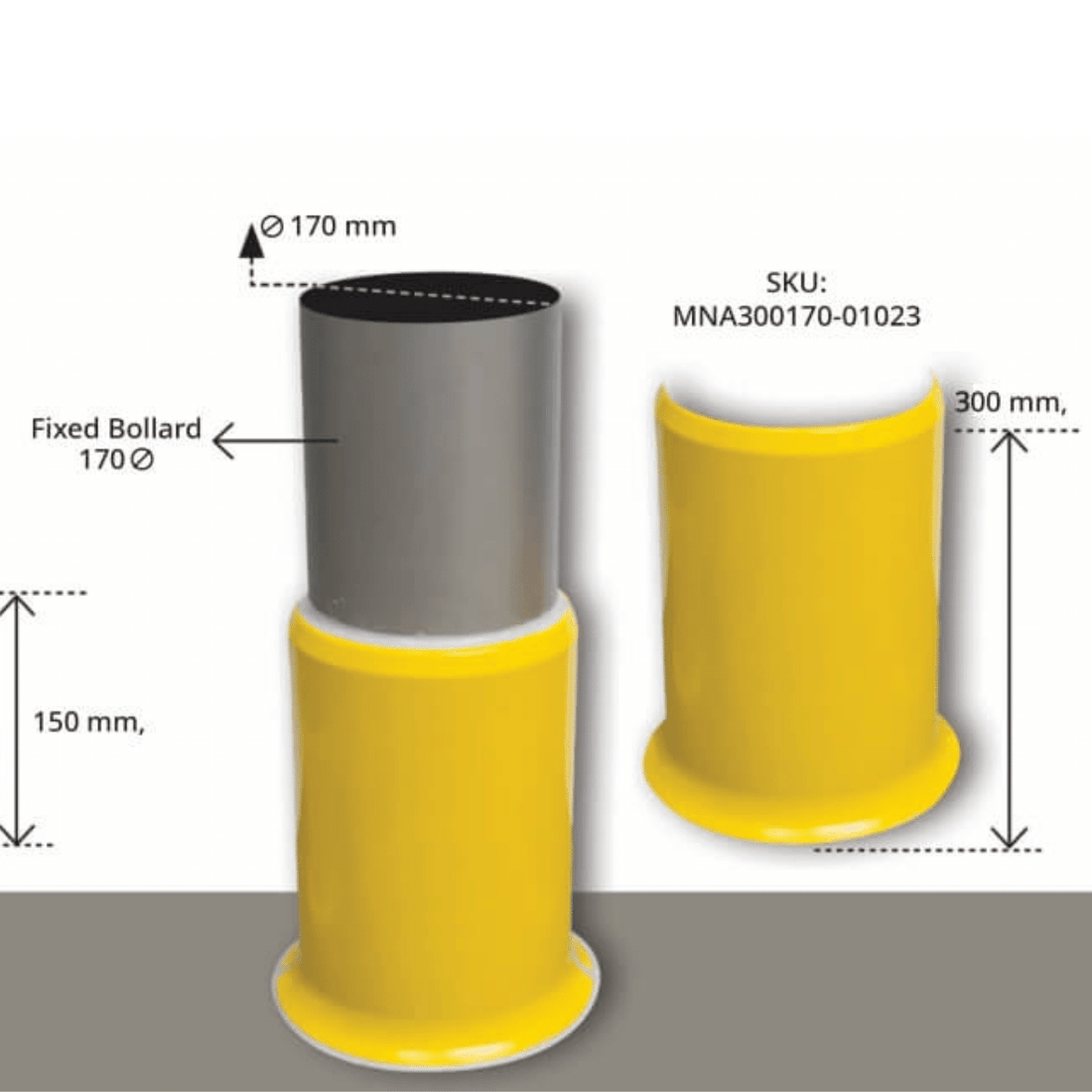

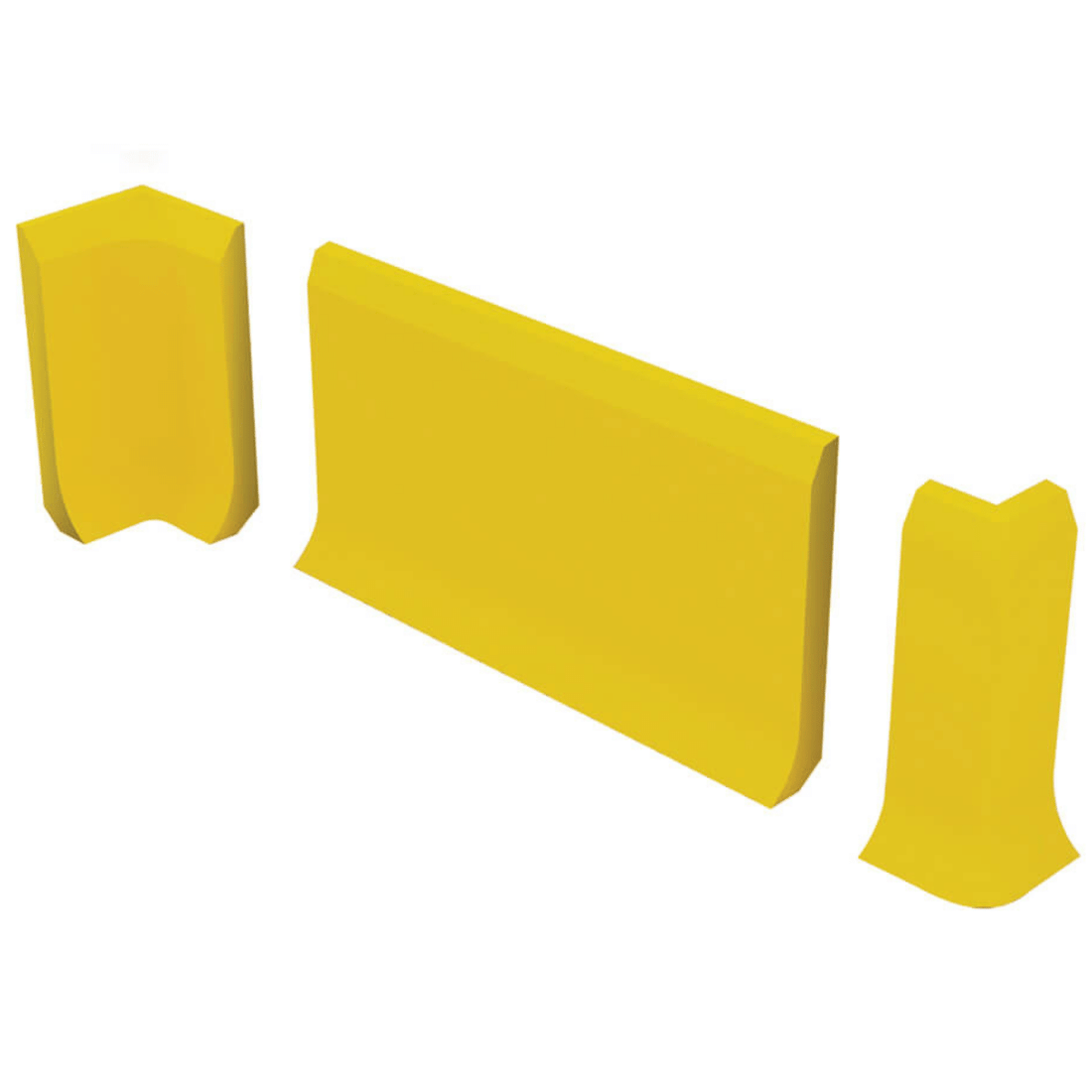

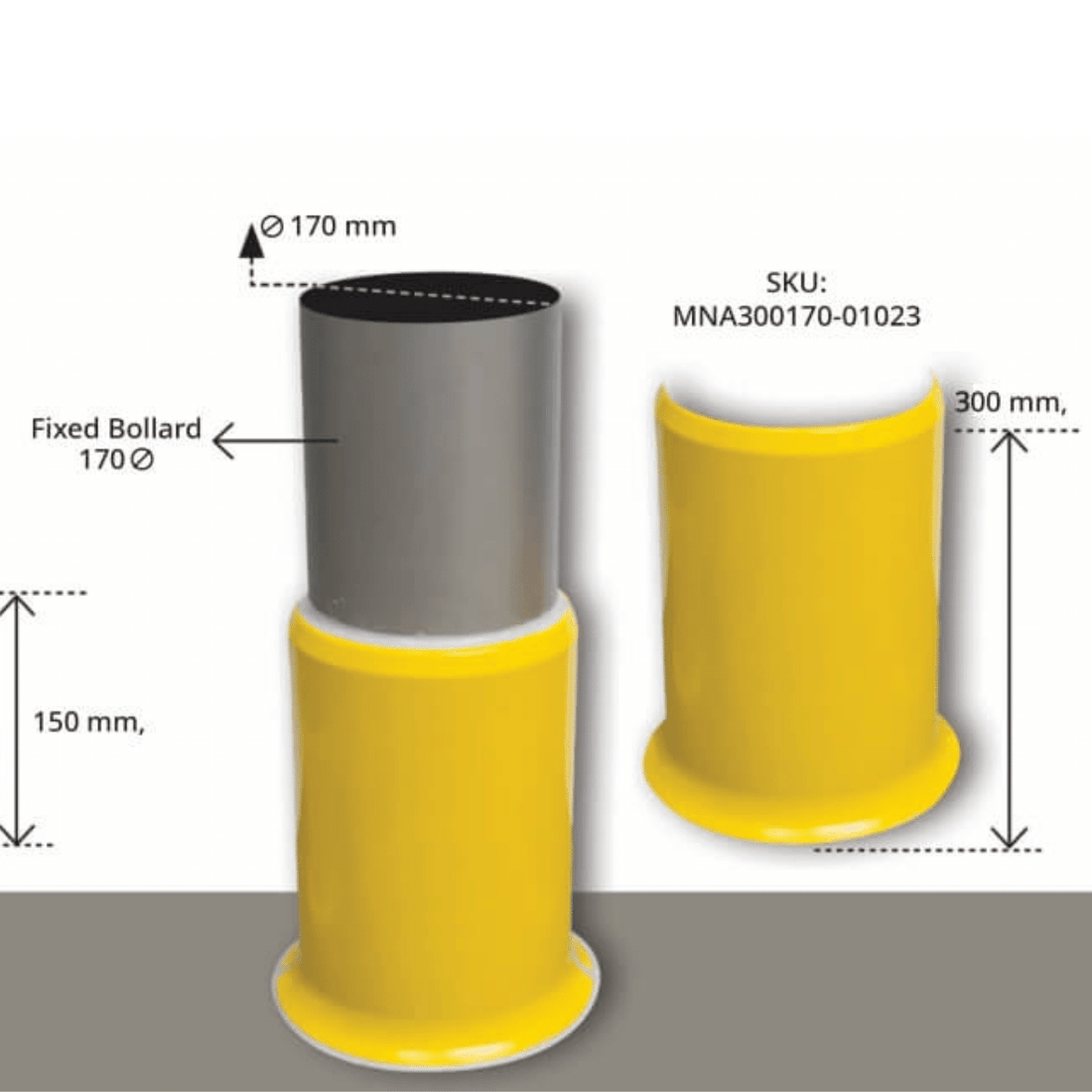

Hygienic Column Skirting 300x170mmHygienic Column Skirting 300x170mm

Hygienic Column Skirting 300x170mmHygienic Column Skirting 300x170mm- Regular price

-

0.00TL - Regular price

-

- Sale price

-

0.00TL

-

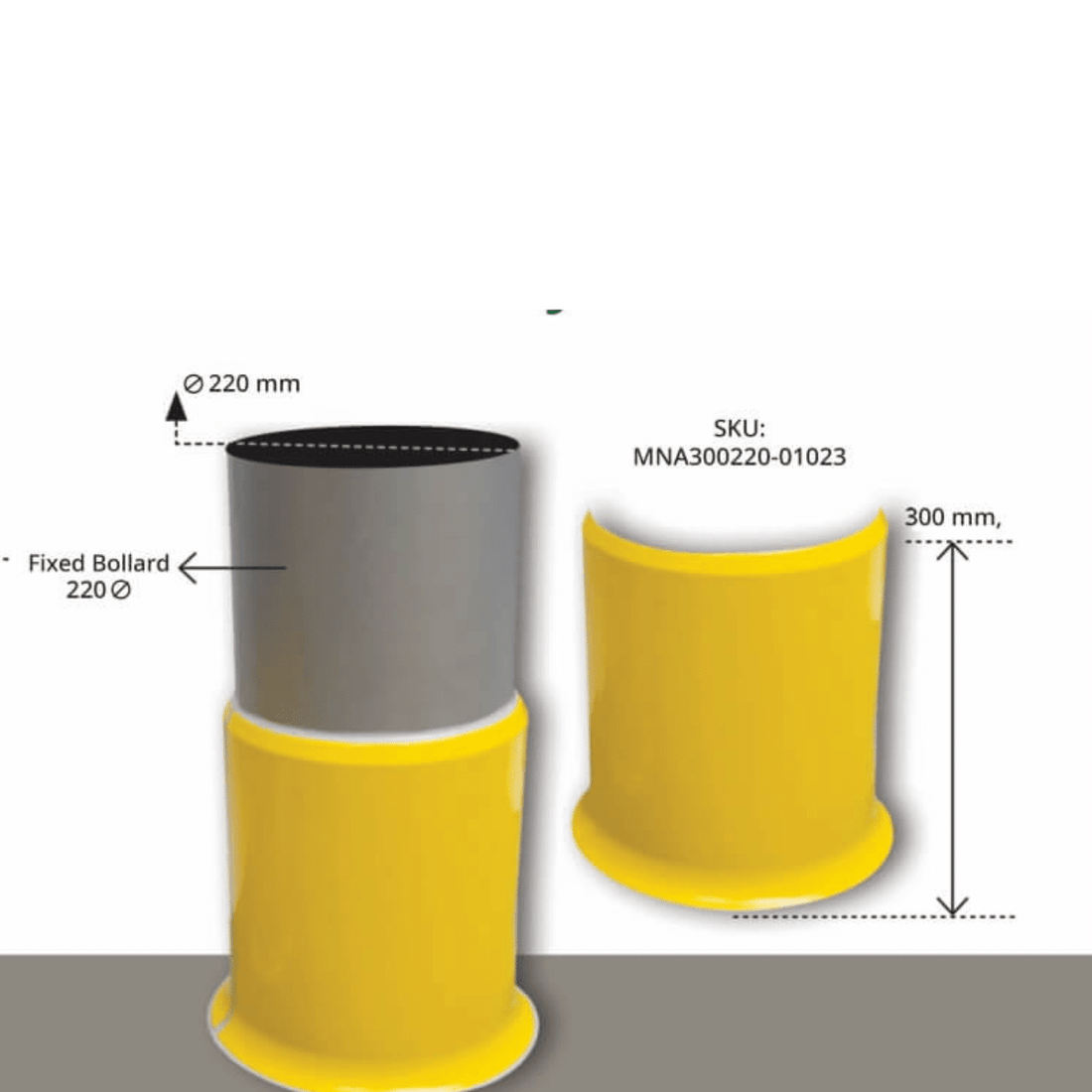

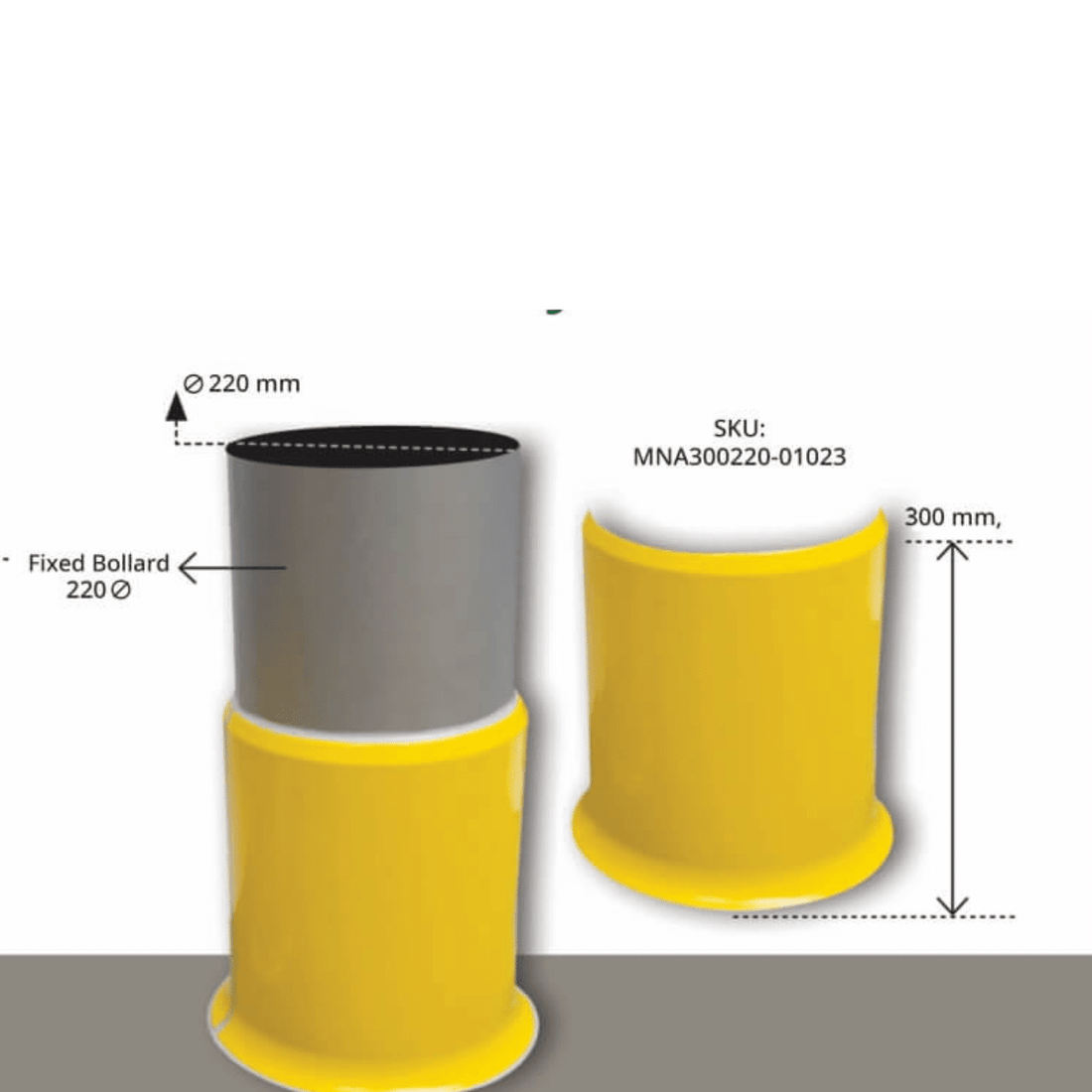

Hygienic Column Skirting 300x220mmHygienic Column Skirting 300x220mm

Hygienic Column Skirting 300x220mmHygienic Column Skirting 300x220mm- Regular price

-

0.00TL - Regular price

-

- Sale price

-

0.00TL

-

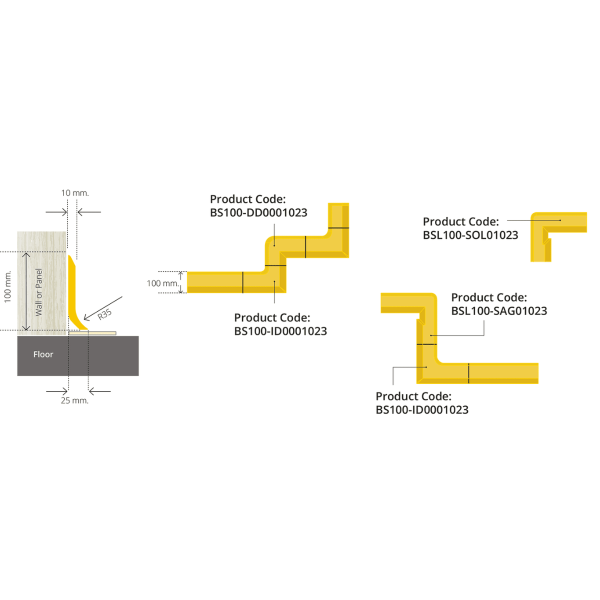

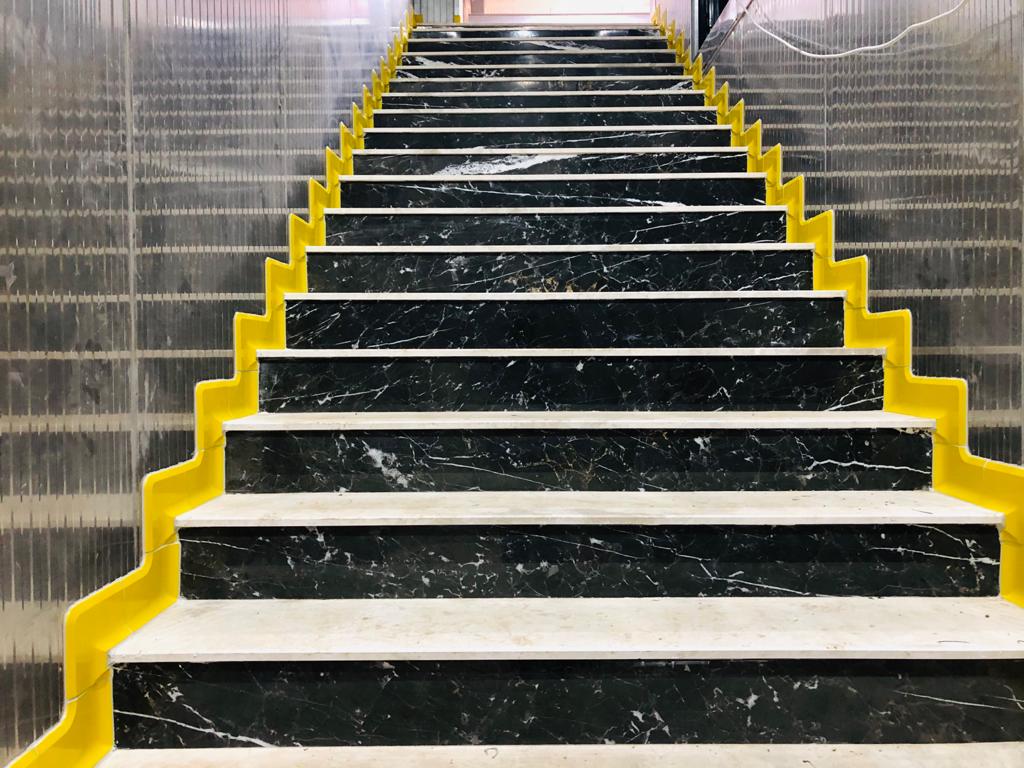

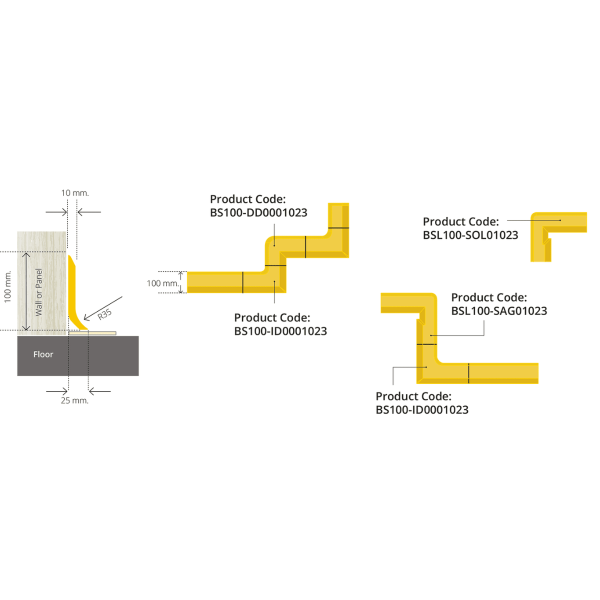

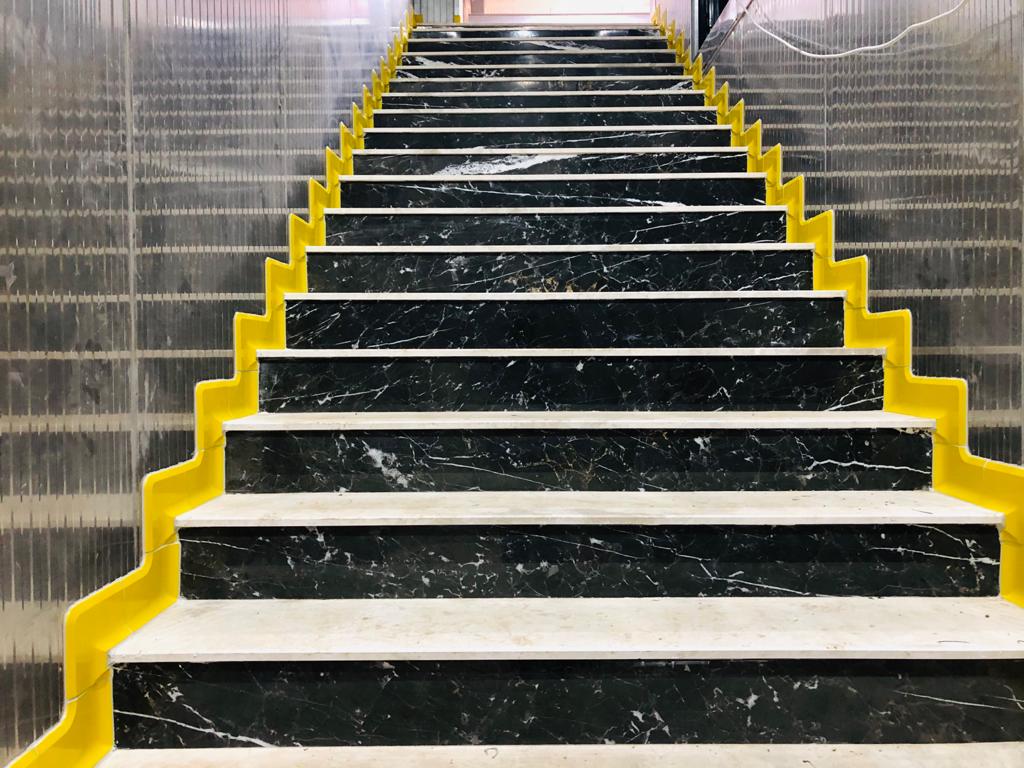

Hygienic Stairs Skirting 100x10mmHygienic Stairs Skirting 100x10mm

Hygienic Stairs Skirting 100x10mmHygienic Stairs Skirting 100x10mm- Regular price

-

0.00TL - Regular price

-

- Sale price

-

0.00TL

Hygienic skirting board are products with smooth surfaces, resistant to chemicals and acids, used on walls, panels, columns and panel bottoms. Commercial kitchen skirting is needed especially in food production factories and hospitals, wall, panel and column bottoms are the areas where bacteria formation is most intense.

Since these areas can often be overlooked during cleaning, there are problems with maintaining hygiene in these areas. However, hygienic skirting boards prevent the formation of bacteria even in the most inaccessible places and are easy to clean because of their radius form.

Hygienic skirting also protects the bottoms of walls and panels against impacts. Especially in factories where food is produced, commercial kitchen skirting is used extensively to create an antibacterial environment and to prevent the reproduction and forming of bacteria that will harm food.

In many areas from the food sector to the health sector, hygienic skirting boards help to create a hygienic, clean and stylish air in details. In addition to providing hygiene, skirting boards protect walls and panels. It prevents objects in contact with the floor area and living things that we cannot see with our eyes from forming in this area or to contact with the wall. These hygienic wall protection products are support elements that also protect walls and panels against corrosion.

Its surface is antimicrobial and does not allow the growth of dirt and microorganisms. Also hygienic skirting products made of polymer material with Migration Test Certificate (Food Contact Suitability Test) do not contain glass fiber for food safety.

Usage Areas of Hygienic Skirting Board

Commercial kitchen skirting, also known as antimicrobial skirting, is used in areas that require high-level hygiene processes. In food production areas, measures should be taken to prevent the formation of bacteria and ensure all hygiene conditions.

In sectors that require high hygiene, such as food and health, special skirting panel protectors are used to emphasize quality and hygiene in cold rooms, which are used as storage areas. They are the best solutions to provide a hygienic environment in all cold product processing and storage areas.

Usage areas of hygienic skirting boards;

Food processing plants that process raw materials such as fruits, vegetables, cereals and meats and transform them into convenience food products such as canned foods, frozen foods or bakery products.

- Facilities processing milk and other dairy products such as cheese, yogurt and butter,

- Facilities producing beverages such as fruit juices, carbonated drinks and alcoholic drinks,

- Facilities for the preparation and baking of bread, cakes, pastries and other bakery products,

- Confectionery facilities producing candies, chocolates and other sweet treats,

- Food packaging facilities that package and label convenience food products for distribution and sale,

- Commercial kitchens that prepare and cook food for sale in restaurants, cafes and other food service establishments,

- Textile, chemistry and cosmetics sectors,

- Malls and supermarkets,

- These products used in many areas such as hospitals, laboratories, pharmaceutical factories and pharmaceutical warehouses in the health sector.

Important Features of Hygienic Skirting Boards

Cleaning materials, preferred equipment and additional support products used in facilities that require hygiene should be specially chosen. Hygienic skirting boards provide protection in the sections between walls, panels and columns in the areas where they are applied. These products are not affected by impacts in the areas where they are used and provide perfect protection against impacts.

In many branches of industry, multistorey and high transportation vehicles are used during the transportation of products in production and storage areas. When the vehicles used in the process of bringing and distributing the products hit the walls and columns, paints may be removed in these areas or fractures may occur due to impacts. However, hygienic skirting boards protect the hygienic walls and columns against all impacts with their robust structure.

In some facilities that require high hygiene, acids and chemicals are also used in the production process. Acids and chemicals can damage walls and panels. Hygienic skirting boards protect the areas from acids and chemicals.

Because of hygienic skirting boards designed in a flexible structure, they reduce the damage in case of impact and protect walls, panels and corners. The valuable equipment in your facilities will not be damaged by the impacts. You can protect your facility from the negative effects of impacts thanks to the hygienic skirting you choose for your needs.

Technical Features of Hygienic Skirting Board

Hygienic skirting has a radius form. This form allows easy cleaning usage areas. Thus, it minimizes the formation of bacteria in areas that should have a hygienic environment. It also provides perfect protection against corrosion.

Hygienic skirting boards are produced in extra visible colors. Thus, it also acts as a "Warning Band" in the areas where it is located. The products are produced over the floor covering and in front of the floor covering according to your needs.

Hygienic skirting models above the floor covering are produced in heights of 10 cm, 15 cm, 30 cm and 100 cm to meet different needs. Floor covering front panel protector models are 165 mm high products. These products, which are mostly preferred in facilities where cleaning and hygiene should be ensured, add an aesthetic atmosphere to the environment with both its form and remarkable color.

You can find flexible hygienic skirting boards for your different needs as well as models in front of the floor covering. Among our products, you can find our 50 cm long Flexible Wall Protection EDK 50, Flexible Wall Corner Protection EKK 50 and EKK100 used on wall and panel corners, Flexible Wall Corner Protection Radius EKK 50-R models that can also be applied on hygienic skirting boards thanks to its radius inner corner on walls and panel corners.

If you work with multistorey and tall transportation vehicles in the area where hygienic skirting boards are used, you can also purchase the KUDK 1500 model with a height of 150 cm to provide protection against impacts at higher points.

If you want protection against impacts on walls, panels and corners in industrial facilities and facilities that require a high level of hygiene, you can choose the best for you from our shock-absorbing skirting models.

Differences Between Hygienic Skirting and PVC Skirting

Hygienic skirting and PVC skirting are two different types of skirting boards that are commonly used.

We produce our hygienic skirting boards from food-grade polymer material that does not contain glass fiber. Our products designed to be easy to clean, hygienic and resistant to bacterial growth, this type of skirting board is especially suitable for use in areas where hygiene is very important and hygienic walls, such as commercial kitchens, hospitals and food processing facilities.

On the other hand, PVC skirting is made from polyvinyl chloride (PVC), a synthetic plastic. This type of skirting is often used in residential and commercial buildings as a protective covering to seal the joint between the wall and the floor. PVC skirting is available in a variety of colors and finishes to match the decor of the area where it will be applied and is often used as a cost-effective alternative to wooden skirting.

In summary, the main difference between hygienic skirting and PVC skirting is their usage intention and the materials they are made of. While hygienic skirting is designed for use in environments where hygiene is priority, PVC skirting is a cost-effective option for residential and commercial spaces.