Sandwich Panel Protectors: The Key to Durability in Industrial Facilities | Vibroser

Sandwich panels used in industrial facilities are preferred for their high insulation performance, hygienic surface structure, and fast installation advantages. However, these panels are exposed to impacts, scratches, and deformation risks, especially in high-traffic areas. Therefore, using the right protection products is essential to extend the lifespan of the panels and enhance facility safety.

Vibroser sandwich panel protectors and hygienic skirting systems offer professional solutions to protect panel surfaces against impacts, maintain hygiene, and reduce maintenance costs.

Why Should Sandwich Panels Be Protected?

Sandwich panels are particularly prone to damage in the following areas:

· Forklift and pallet truck traffic

· Product handling operations

· Storage processes

· External factors and accidental impacts

· Food processing areas where hygiene is critical

Such damage not only affects appearance but can also lead to insulation loss, hygiene issues, and high maintenance costs.

Advantages of Vibroser Panel Protectors

1. Maximum Protection Against Impacts

Thanks to their steel structure and specially engineered design, Vibroser panel protectors shield panels from forklifts, hand trucks, and equipment collisions.

2. Long-Lasting Structure and Durability

Their corrosion-resistant material ensures long-term performance even in high-humidity and demanding environments.

3. Easy Installation and Compatible Design

Customizable to fit any facility, the protectors can be installed easily without damaging existing panel surfaces.

4. Compliance with Hygiene Standards

In food production facilities, cold storage rooms, and hygiene-sensitive environments, Vibroser hygienic skirting systems prevent bacteria buildup at wall-floor joints and simplify cleaning.

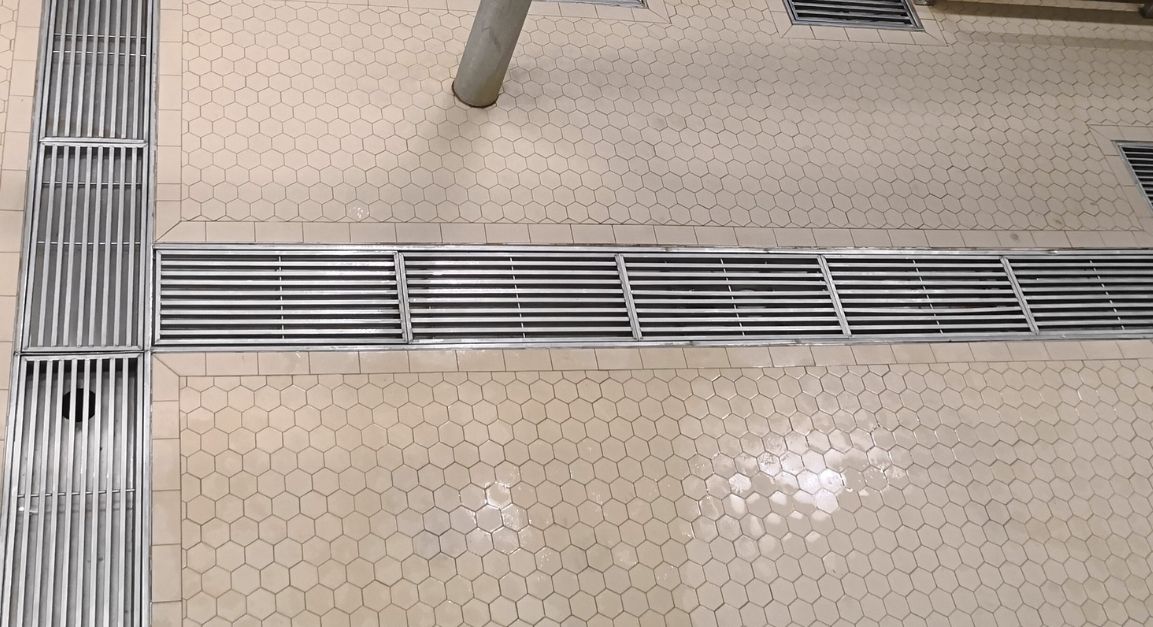

Integrated Protection with Vibroser Hygienic Skirting

The base joints of sandwich panels are some of the areas where dirt and bacteria accumulate most.

With their curved structure, Vibroser hygienic skirting systems:

· Prevent dirt accumulation

· Make cleaning easier

· Enhance overall hygiene standards

· Protect the bottom of the panels from moisture and impacts

This ensures that sandwich panels last longer while maintaining maximum hygiene within the facility.

Where Are They Used?

Vibroser panel protector and hygienic skirting solutions are widely used in the following sectors:

· Food production facilities

· Meat and dairy processing plants

· Cold storage and refrigeration rooms

· Logistics and warehousing areas

· Industrial facilities

· Clean rooms and laboratories

Vibroser Panel Protectors and Hygienic Skirting Systems

To increase the durability of sandwich panels, ensure facility safety, and maintain the highest hygiene standards, Vibroser panel protectors and hygienic skirting systems provide professional and long-lasting solutions. With the right protection systems, you can reduce maintenance costs and create a safer, more durable production environment.