Steel Kerb Solutions: A New Era of Sanitary Industrial Design

Steel kerb, specifically designed for hygienic wall and floor connections, has become increasingly vital in various industries. The steel kerb profiles, particularly those by Vibroser, are engineered to meet the stringent demands of Food, Meat, Dairy, Drinks, and Pharmaceutical processing factories. These stainless steel kerbing profiles are ideal for central division walls and other critical areas in these environments. Their design includes integrated support sections with spaced bolt down points, and they feature a modular system that accommodates all design requirements. Moreover, bespoke options for the steel kerb are available on request, ensuring a perfect fit for any specific needs.

In commercial and industrial settings, the role of the steel kerb is indispensable. Vibroser’s steel kerb solutions offer essential hygienic benefits, crucial in environments where cleanliness and safety are top priorities. These steel kerb profiles are not only highly functional but also adaptable to various industry needs. They are designed to cater to the unique requirements of diverse sectors, providing a hygienic and robust solution for wall and floor connections. The adaptability of the steel kerb is further emphasized by the availability of customizable options, making it an invaluable component in maintaining high hygiene standards in critical processing and manufacturing areas.

Blending Durability with Design in Food Industry

In the specialized sector of food and catering, where maintaining strict hygiene standards is critical, the implementation of the Vibroser stainless steel kerbing has become increasingly prominent. This steel kerb is specifically engineered for scenarios that necessitate a sanitary junction between the wall and floor areas. Its construction from top-grade stainless steel not only ensures long-lasting durability but also provides remarkable resistance to impacts. Once this steel kerb is installed, it can be further fortified with concrete, enhancing its resilience. This additional reinforcement allows the steel kerb to withstand the rigorous demands of daily operations, including the frequent movement and impacts from trolleys, pallet trucks, and forklifts. Furthermore, the design of this steel kerb plays a crucial role in eliminating any crevices between the wall and the floor, effectively preventing the accumulation of bacteria. This feature is particularly important as it aligns with the latest health and safety guidelines, ensuring a cleaner and safer environment.

Moreover, the Vibroser stainless steel kerbing is not just about functionality; it also contributes aesthetically to the work environment. The sleek appearance of the steel kerb blends seamlessly with modern kitchen and catering designs, adding a professional touch to the workspace. Its ease of cleaning is another vital attribute, as regular maintenance can be performed swiftly and efficiently, ensuring that the steel kerb remains hygienic and visually appealing. The compatibility of this steel kerb with various flooring types makes it a versatile solution for numerous food processing and catering facilities. By installing the Vibroser stainless steel kerbing, businesses not only comply with stringent hygiene standards but also invest in a durable solution that enhances both the safety and appearance of their workspaces.

Seamless and Sanitary

Vibroser’s range of steel kerb profiles is expertly crafted to cater to environments that require hygienic floor and wall connections, a critical aspect in many industrial settings, particularly in the food and beverage sector. This steel kerb is designed to ensure a seamless and sanitary transition between different surfaces, effectively eliminating any gaps that could harbor contaminants or bacteria. The versatility of this steel kerb is one of its standout features, making it suitable for a wide array of applications. Each steel kerb in this range is constructed with precision, ensuring it meets the specific requirements of each environment, whether it’s for temperature control, moisture resistance, or chemical exposure. Moreover, the durability of this steel kerb guarantees long-term performance, reducing the need for frequent replacements and maintenance.

In addition to the standard range, Vibroser also offers an alternative selection of steel kerbs that are made from hygienic materials and coated with a resin finish. This innovative approach ensures a uniform and smooth surface, aligning perfectly with the European Hygienic Engineering & Design Group (EHEDG) guidelines. This variant of the steel kerb is particularly beneficial in environments where cleanliness and contamination prevention are paramount. The resin-coated steel kerb not only enhances the hygienic properties but also contributes to the aesthetic appeal of the space, offering a clean and professional look. This adaptability makes Vibroser’s steel kerb range ideal for a variety of settings, from food processing plants to pharmaceutical laboratories, where hygiene and cleanliness are non-negotiable. With these options, businesses can select the steel kerb that best suits their specific needs, ensuring both compliance with health standards and the longevity of their infrastructure.

The Smart Choice for Easy-to-Maintain Hygienic Environments

The steel kerb products offered by Vibroser are a testament to high-quality engineering, made from AISI 304 and AISI 316L grade stainless steel. This choice of material ensures that each steel kerb exhibits exceptional durability and resistance to a variety of challenging elements. Notably, these steel kerbs are meticulously designed to be food safe and hygienic, catering specifically to environments where cleanliness and safety are paramount. Their resistance to acids, chemicals, impacts, scratches, and extreme temperatures makes them a reliable choice in demanding conditions. Furthermore, the inherent properties of the steel kerb make them resistant to dirt, stains, and corrosion, while also possessing antimicrobial and antibacterial qualities. This dual protection against microbial growth and environmental damage ensures that these steel kerbs maintain their integrity and hygienic standards over time.

In addition to their robust construction, the non-porous surface of the steel kerb is a significant advantage. This feature ensures that dirt, germs, and other contaminants cannot settle or harbor within the material, making them exceptionally easy to clean and maintain. The practicality of these steel kerbs extends to their assembly as well; they are designed for straightforward installation and can be applied to all types of ground, making them versatile for various applications. Moreover, their HACCP certification is a clear indicator of their compliance with international health and hygiene standards. This certification underscores the commitment of Vibroser to deliver steel kerbs that not only meet but exceed industry requirements, providing an efficient and hygienic solution for businesses that prioritize health and safety in their operations.

Tailor-Made Steel Kerbs by Vibroser: Perfect Fit for Your Specific Needs

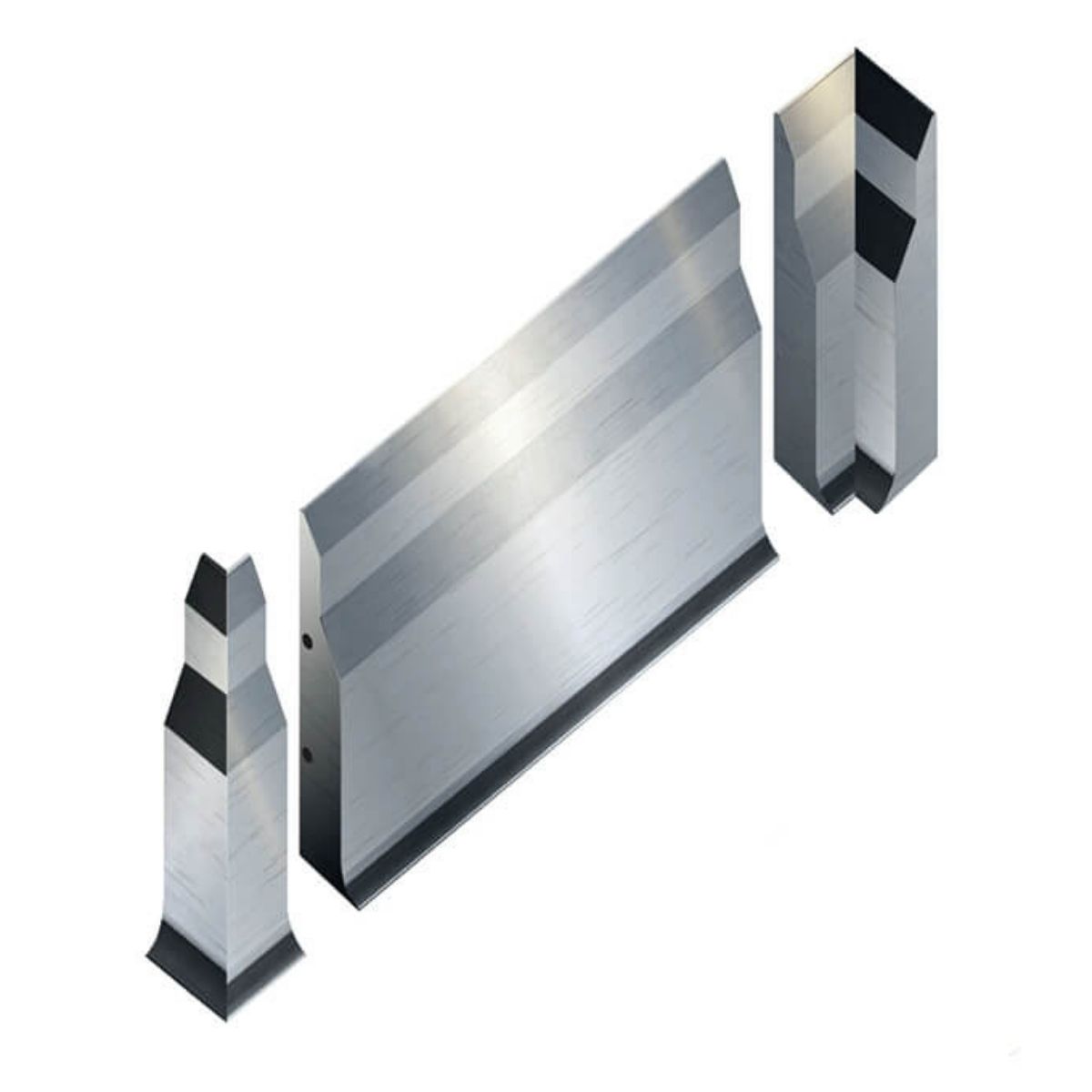

Vibroser steel kerbs are available in tailored profiles and lengths to suit specific locations. The benefits of these steel kerbs include pre-made internal and external corners, single solutions, and access to a technical design team for individual application advice. Lastly, Vibroser offers a comprehensive service including survey, design, and installation of the steel kerb, ensuring that each installation is optimized for its specific context.