Interlocking Acid Proof Tile 100X150 Brown

Interlocking Acid Proof Tile is produced in 100×150 dimensions and 15 or 18mm thickness. Slip resistance values: R9-R10-R11-R12.

Interlocking Acid Proof Tile 100×150 is a ceramic flooring material that is not affected by acids and chemicals. It has a bonding channel on the back side that increases the adhesion strength and its hinged edges are tapered. Thanks to its solid surface, it is non-slip and non-corrosive. It is not affected by temperature differences and has a long lifespan.

Interlocking Acid Proof Tile products are preferred for hygienic and long-lasting floors in industrial facilities. Especially in areas where qualified health and hygiene processes are dominant, such as the food industry, the industrial acid proof tile flooring system has become a standard rather than an option. Anti-acid tile product group provides a high level of durability in terms of mechanical, thermal and chemical properties on floors which exposed to chemicals. This makes long-term use is possible. For this reason, it is possible to state that the acid proof tile group has a wide usage area.

Where Interlocking Acid Proof Tile is Used?

Interlocking Acid Proof Tile is mainly used in the food industry and follows as;

- Meat and dairy facilities,

- Wholesale fish markets,

- Bakeries, pastry shops,

- Places of mass food production,

- Vegetable and animal fat production factories,

- Production facilities in the automotive sector,

- Car services and showrooms,

- Textile sector,

- Chemistry sector,

- Cosmetics sector,

- Shopping centers, supermarkets and DIY stores,

- Hospitals, laboratories, pharmaceutical factories, pharmaceutical warehouses in the health sector,

- Transportation sector at bus terminals, metro stations and airports,

- Power plants,

- Tourism sector.

In many sectors, it is preferred in acid proof hygienic floor applications that are resistant to heavy loads and chemicals. For this reason, it is possible to say that it has a wide usage area.

What are the Features of Interlocking Acid Proof Tile?

Interlocking Acid Proof Tile, an industrial floor product, is pressed at 4600 tons of pressure and placed in an industrial oven at 1200 degrees. It is the most robust and durable material in the construction industry. The features of industrial acid proof porcelain tiles used in areas where high hygiene standards must be applied are as follows;

- Non-slip and non-wear because of its solid surface,

- Unaffected by chemicals, oils and acids,

- Resistant to high temperatures,

- Resistant to heavy substances and intensive use,

- It has higher strength than concrete flooring materials,

- Due to its density, it does not produce bacteria and does not host dirt,

- Easy to clean and requires no routine maintenance,

- It does not change color as it is made of natural materials,

- Long life span,

- Environmentally friendly.

You can view all our products here.

What is Vibratory Application Technique?

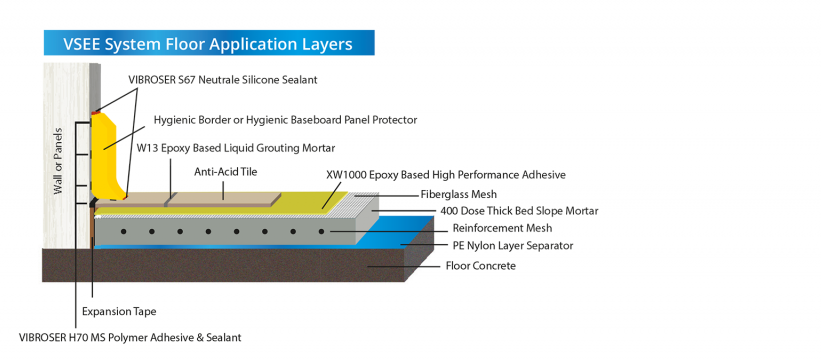

Vibratory application technique in industrial anti-acid porcelain tile flooring begins with removing the existing concrete floor from dirt. The concrete floor is cleaned from dirt, spilled sand, and waste by pressurized water washing machines. After cleaning the floor, the mortar is poured, where the anti-acid tiles will be combined with the floor. After the mortar is poured, the floor is improved to get a smooth floor. Thus, the floor, which is both flat and clean, is made suitable for the placement of anti-acid tile floor mortar. High-quality adhesives are applied to the fresh mortar. After applying high-quality adhesive, anti-acid tiles are assembled parallel to the rope and miter.

After the tile installation process, pre-compression is performed, ensuring no space between the floor and the tiles. This technique is called the vibratory compression technique because horizontal and vertical vibration movements are used during compression. After all these applications, it should be left for a while for the floor to become suitable for the application. In this process, the tiles are frozen by the mortar’s own heat, as the water absorption rate is zero. After the vibration process is completed and left for a while, a dust vacuum process is applied to clean the surfaces. Then, a liquid epoxy filling is applied to the joints.

+ VSEE VIBRATION SYSTEM XW1000 is epoxy bonding and W13 liquid epoxy grouting application system;

it has been accepted in facilities with (-40 – +70) degrees heat environment on the floors of food factories in developed countries. The VSEE system is a CE-certified XW1000, gel paste type epoxy-based adhesive and epoxy-based W13 liquid joint filler application, which has been specially developed for the vibratory application method and has a much higher adhesion strength than its counterparts, and is also applied with a machine system.

VSEE is an indispensable solution for installations that require particularly high mechanical strength. Solving the solid and long-lasting floor needs of hot and cold rooms, acidic and caustic environments of all kinds of food, meat, milk, fish, beverage, and bakery product producers. It is a system where masters made 400 doses of m3 400 kg of cementitious thick bed mortar and ceramic application on the same day and saved time. It is the most economical and guaranteed solution with minimum maintenance cost in the long term.

+ VSFF VIBRATION SYSTEM; flex adhesive and flex joint filler application system;

It is an economical application that uses the advantages of vibrating system application with high strength two-component C2TE S1 class flex adhesive and CG2 class flex joint filler. Therefore, it is a suitable system especially for industrial facilities that require medium-light mechanical strength (markets etc.) and operate at dry and normal temperatures.

It is the most economical solution alternative thanks to its minimum maintenance requirement. Also, it is a time-saving system, thanks to the application of 400 doses of thick bed mortar and joint filling with ceramics on the same day.

+ VSFE VIBRATION SYSTEM flex bonding and W13 epoxy joint filler application system

It is a high-strength cement-based, two-component C2TE S1 class flex adhesive and machine system epoxy-based W13 liquid joint filler application. This is a suitable system, especially for industrial facilities that require medium and weak chemical resistance and medium-light mechanical strength.

It is a time-saving system, thanks to the application of 400 doses of thick bed mortar and ceramics in the same day while solving the floor needs of all kinds of meat, milk, fish, beverage, and bakery product producers in acidic and non-caustic environments. Thanks to its minimum maintenance requirement, it is also a cost-effective solution alternative

VSEE VIBRATION SYSTEM XW1000 is epoxy bonding and W13 liquid epoxy grouting application system;

it has been accepted in facilities with (-40 – +70) degrees heat environment on the floors of food factories in developed countries. The VSEE system is a CE-certified XW1000, gel paste type epoxy-based adhesive and epoxy-based W13 liquid joint filler application, which has been specially developed for the vibratory application method and has a much higher adhesion strength than its counterparts, and is also applied with a machine system.

VSEE is an indispensable solution for installations that require particularly high mechanical strength. Solving the solid and long-lasting floor needs of hot and cold rooms, acidic and caustic environments of all kinds of food, meat, milk, fish, beverage, and bakery product producers. It is a system where masters made 400 doses of m3 400 kg of cementitious thick bed mortar and ceramic application on the same day and saved time. It is the most economical and guaranteed solution with minimum maintenance cost in the long term.

VSFF VIBRATION SYSTEM; flex adhesive and flex joint filler application system;

It is an economical application that uses the advantages of vibrating system application with high strength two-component C2TE S1 class flex adhesive and CG2 class flex joint filler. Therefore, it is a suitable system especially for industrial facilities that require medium-light mechanical strength (markets etc.) and operate at dry and normal temperatures.

It is the most economical solution alternative thanks to its minimum maintenance requirement. Also, it is a time-saving system, thanks to the application of 400 doses of thick bed mortar and joint filling with ceramics on the same day.

VSFE VIBRATION SYSTEM flex bonding and W13 epoxy joint filler application system

It is a high-strength cement-based, two-component C2TE S1 class flex adhesive and machine system epoxy-based W13 liquid joint filler application. This is a suitable system, especially for industrial facilities that require medium and weak chemical resistance and medium-light mechanical strength.

It is a time-saving system, thanks to the application of 400 doses of thick bed mortar and ceramics in the same day while solving the floor needs of all kinds of meat, milk, fish, beverage, and bakery product producers in acidic and non-caustic environments. Thanks to its minimum maintenance requirement, it is also a cost-effective solution alternative

| Color | Brown |

|---|