A Wall kerb is an industrial wall protection product used to protect walls from damage caused by impact or abrasion. Wall kerbs are made of durable materials such as acrylic or stainless steel. It is hygienic, does not let bacteria formation..

Industrial wall protection is often used in warehouses, factories and other industrial environments where heavy machinery or equipment is moved. It is also used in high-traffic areas such as hospitals, schools and public buildings to protect walls from impacts caused by carts, forklifts and other carrying equipment.

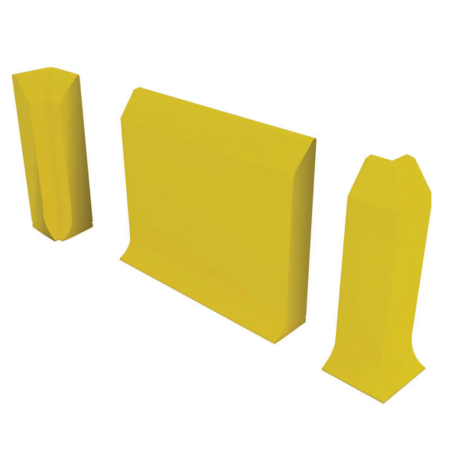

In addition to protecting walls from damage, the wall kerb also helps create a safer environment for employees and visitors. In acrylic wall kerb; yellow color helps to prevent accidents, also serves as a warning band.

Wall kerbs are easy to install and maintain, making them the ideal wall protection solution for many installations.

Where is Wall Kerb Used?

Wall kerb can be used in a variety of industrial environments where floors are cleaned frequently or where there is a need for a smooth and durable barrier between the wall and the floor. Some examples of industrial locations where wall kerbs can be used include:

- Food facilities: In food processing facilities, wall kerbs are used to create a hygienic seal between the floor and the wall. This helps prevent food residuals and bacteria from accumulating in hard-to-clean corners and crevices.

- Pharmaceutical production facilities: Wall kerbs are often used in pharmaceutical production facilities to create a smooth and seamless transition between the floor and the wall. This helps to prevent the formation of microorganisms and helps to ensure a high level of hygiene.

- Laboratories: In laboratories, wall kerbs are commonly used to prevent spills and splashes from leaking onto walls and to create a hygienic barrier between the floor and the wall.

- Cleanrooms: Wall kerbs are often used in cleanroom environments where pollution prevention is critical. They help create a seamless transition between wall and floor, reducing the risk of dirt and bacteria formation.

- In general, wall kerbs are useful products for industrial areas that require high levels of hygiene and cleanliness, as industrial wall protection provides a seamless and durable barrier between the wall and the floor.

What are the Wall Kerb Types?

The choice of wall kerb type depends on the specific requirements of the space and the environment that will be installed. When choosing a wall kerb for the area, it is important to consider factors such as durability, resistance to chemicals and bacteria, ease of maintenance and aesthetics. If it will be used in the food and health sectors, it is important to choose Acrylic and stainless steel wall protectors.

Acrylic Borders: Acrylic wall kerbs, also known as hygienic wall kerbs, are a popular choice for industrial and commercial buildings because they are easy to install and maintain. It is produced from polymer material that is resistant to chemicals, water and impacts. It is designed to be free of glass fiber for safety of food production facilities. Acrylic is also a good choice for outdoor usage as it is resistant to UV rays.

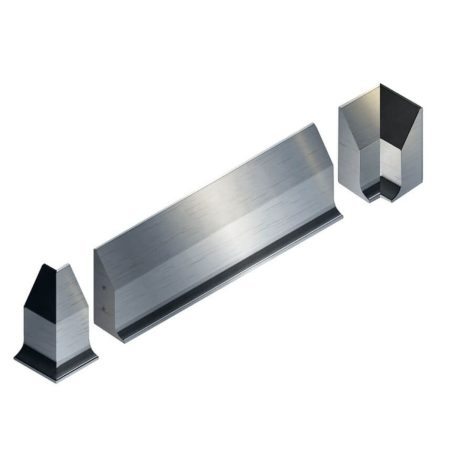

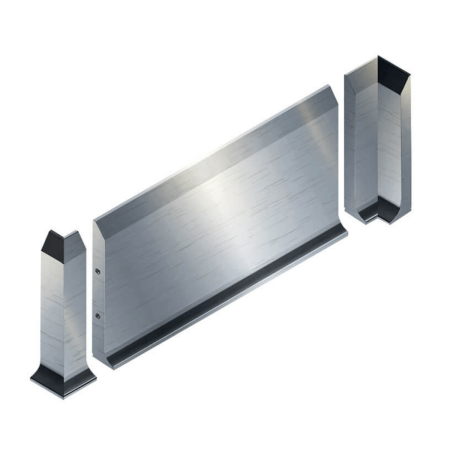

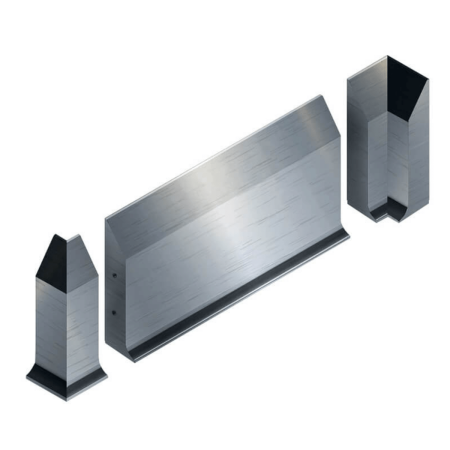

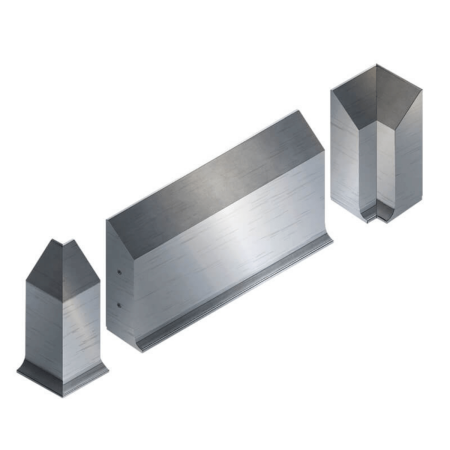

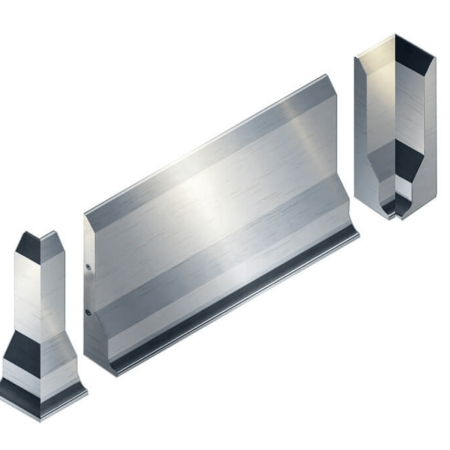

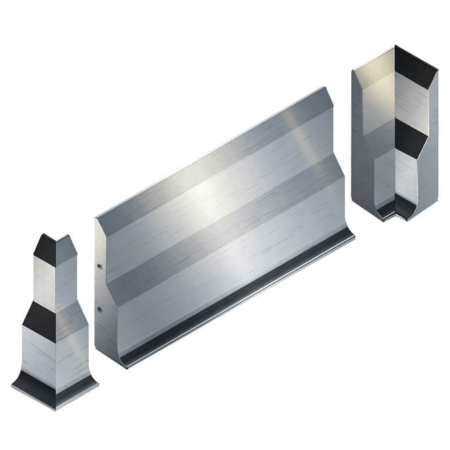

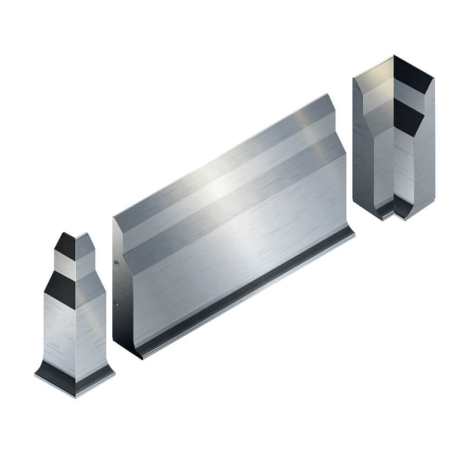

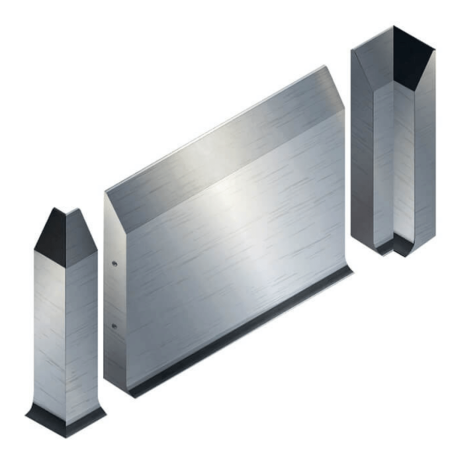

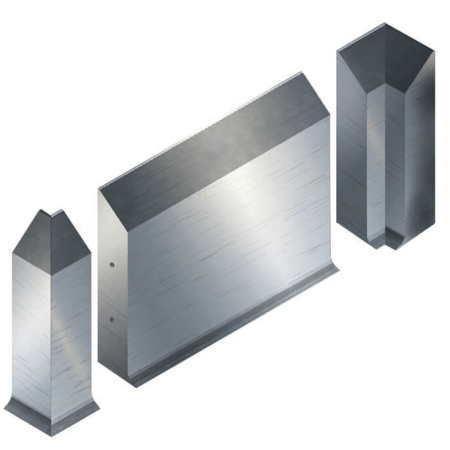

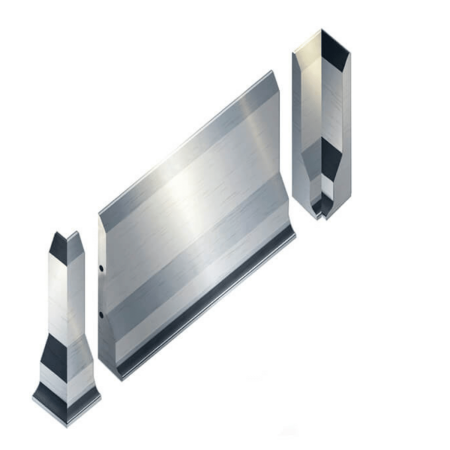

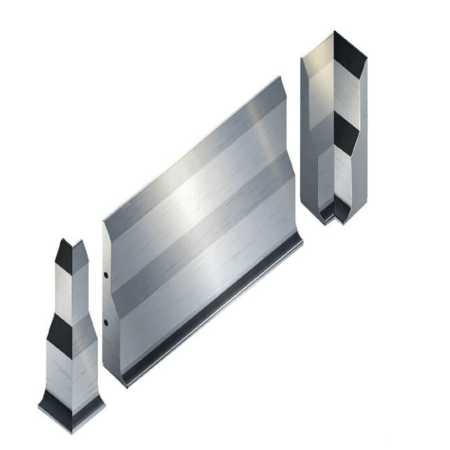

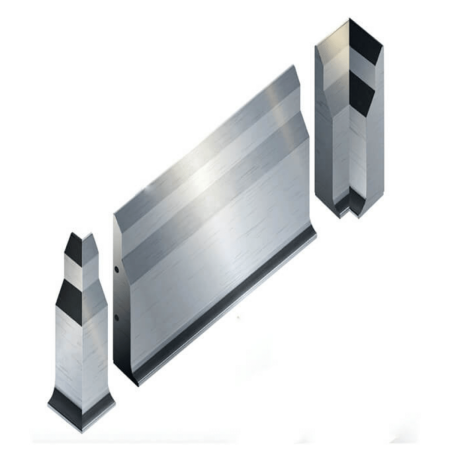

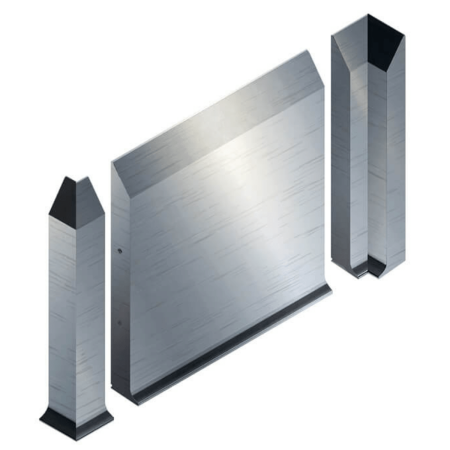

Stainless Steel Wall Kerbs: They are durable and long-lasting options that provide excellent resistance to corrosion and bacteria. They are often used in food processing facilities, cold storage and clean rooms. It is a food-safe material as it is non-reactive, durable and easy to clean and sterilize.

PVC Wall Kerbs: Industrial wall protection is preferred for its strength, chemical resistance and low cost. In general, PVC is not considered inherently food-safe as it can contain harmful additives such as phthalates, which foods may absorb and potentially cause health problems. So it is not recommended for use in food production facilities.

Epoxy Wall Kerbs: This is a resin-based border type that provides resistance to chemicals and abrasion. Generally used in laboratories, areas where spills and splashes are common. If they will be used in food facilities, it is important to follow the manufacturer’s instructions carefully. Even food-grade epoxy should not come into contact with acidic, alcoholic foods or heated foods, as these conditions may cause the epoxy to break down and release potentially harmful chemicals.

Aluminum Wall Kerbs: A lightweight and durable option that is easy to install and maintain. Usually used in commercial buildings. Aluminum wall kerbs are not considered safe for foods, because aluminum can react with acidic or alkaline foods and potentially leach harmful substances into food. This can cause taste and color degradation in food and a health risk may occur.

Concrete Wall Kerbs: A strong and durable option that provides impact resistance. It is widely used in areas that require a high level of durability, such as warehouses. Concrete is a commonly used material for making wall kerbs, but it is not considered safe for food. Concrete is a porous material that can absorb liquids and food particles, making it difficult to clean and sanitize. Concrete can also contain additives such as pigments or aggregates that are not food-safe.